Replace Paper Checklists with Smart Mobile Inspections

Digital inspection platform for machinery OEMs. Build custom templates, capture data with AI scanning and offline mode, get real-time visibility across your operation.

One Platform, Unlimited Inspection Types

From the factory floor to the field, Inspect adapts to every quality control scenario your operation runs.

Pre-Delivery Inspections

Maintenance & Service

Receiving Inspections

Supplier Audits

Safety Inspections

Commissioning & Installation

Plus any other inspection workflow you run -> Build your own templates in minutes

The Real Cost of Paper-Based Inspections

Paper checklists feel simple—until you account for what they actually cost your operation.

Hours of Manual Work Per Machine

Technicians complete inspections on paper. Someone in the office manually transcribes everything into your system. That's administrative work that adds zero value to your operation or your customers.

Zero Real-Time Visibility

Your quality manager has no idea what's happening on the factory floor right now. Which machines are inspection-complete? Which have issues? You won't know until paperwork reaches the office—hours or days later.

Good luck finding that report

A customer reports an issue six months after delivery. You need the original inspection record to verify what left your factory. Now someone's digging through stacks of paper or filing systems hoping it wasn't lost.

Inspecting in Impossible Conditions

Technicians balance clipboards in tight spaces, reaching around machinery or working in greasy areas. Writing notes is tough, leading to missed defects or unreadable documentation.Paper inspection processes also mean:

We've been looking for an automation solution like this for a couple of years now. The current paper-based process is a real drag on the business. What you've built is exactly what we need.

Digital Inspections

That Work Like Your Team Works

Inspect by Machinery Partner replaces paper with a mobile inspection system designed for real factory and field conditions.

Paper Process

Scattered paperwork, delayed data entry, and no way to know what's complete until it's too late.Inspect by Machinery Partner

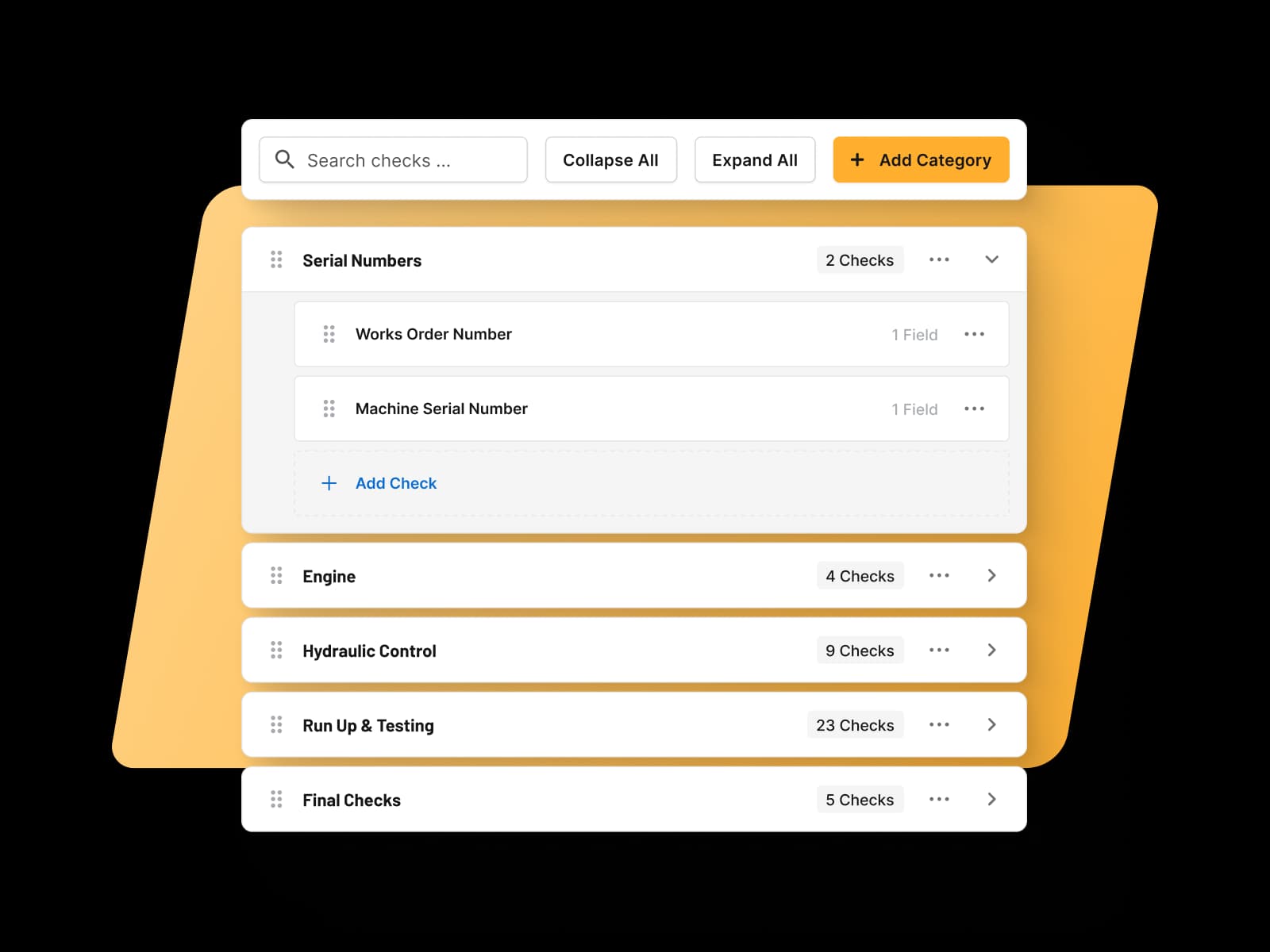

Centralized inspection data captured in real-time with complete visibility and control.Build Custom Templates

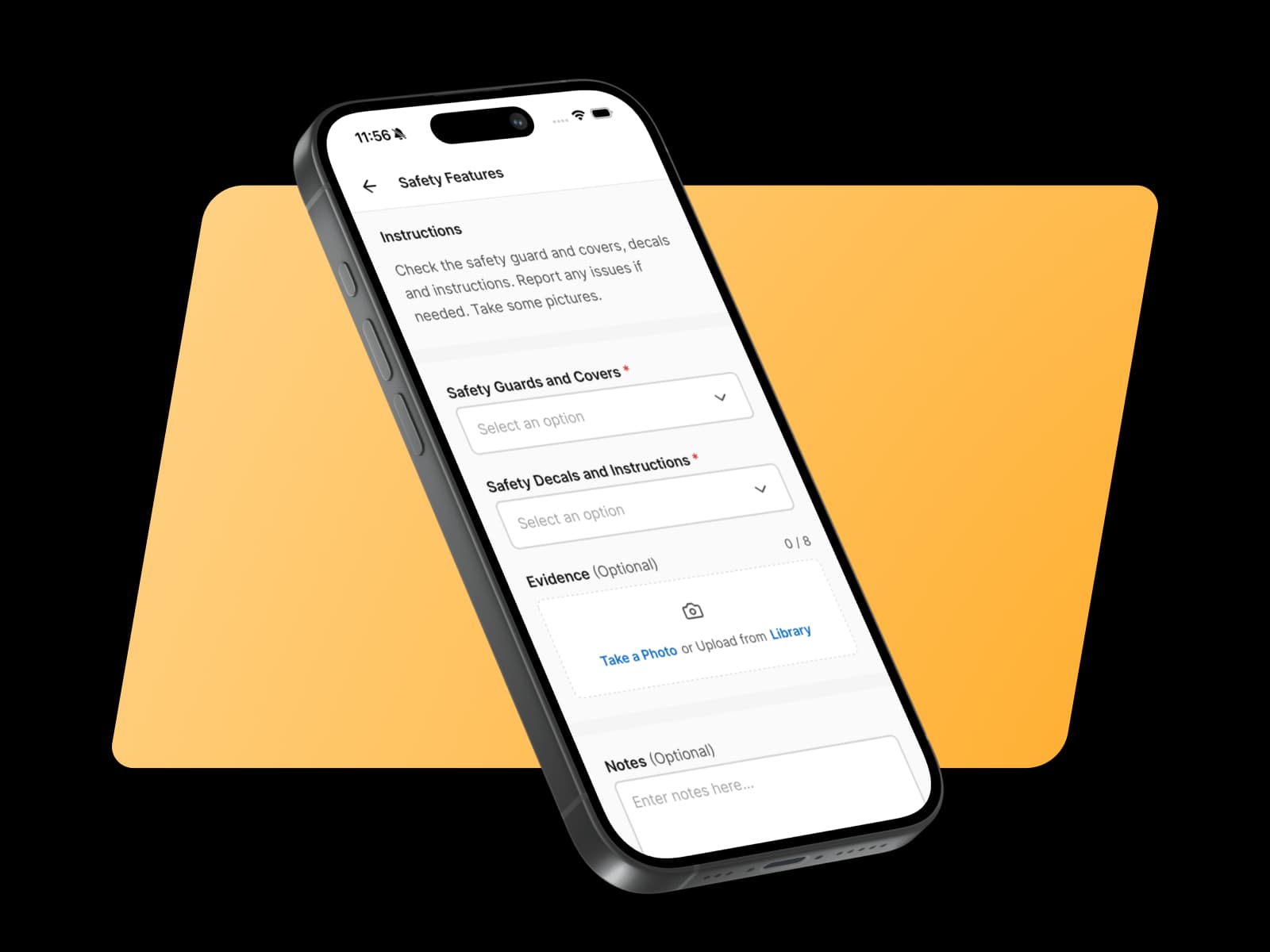

Create inspection checklists tailored to your specific needs. Define check items, set pass/fail criteria, add instructions, and specify required photos. Build templates for different equipment models, inspection types, or customer requirements.

Deploy templates to mobile devices instantly. Make updates anytime and changes roll out to all technicians immediately—no need to reprint and redistribute checklists across locations.

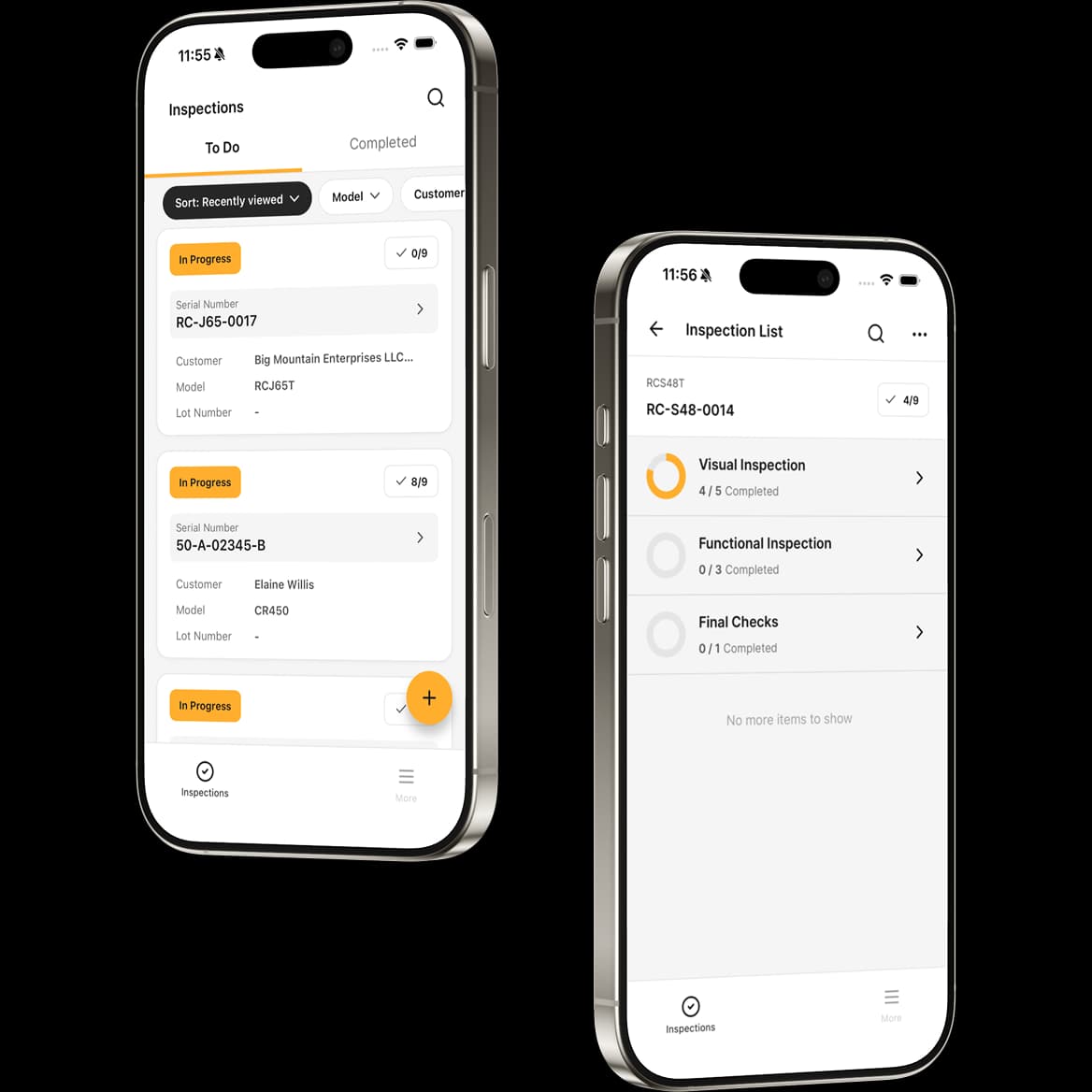

Technicians Complete Inspections on Mobile

Factory workers and field technicians use their phones or tablets to run through guided checklists.

The app uses AI Smart Scan to capture serial numbers automatically. Offline mode allows inspections without internet, ensuring productivity in remote areas. Photo evidence is needed for critical checks. GPS stamps inspection locations for tracking, while help wizards assist with procedures.

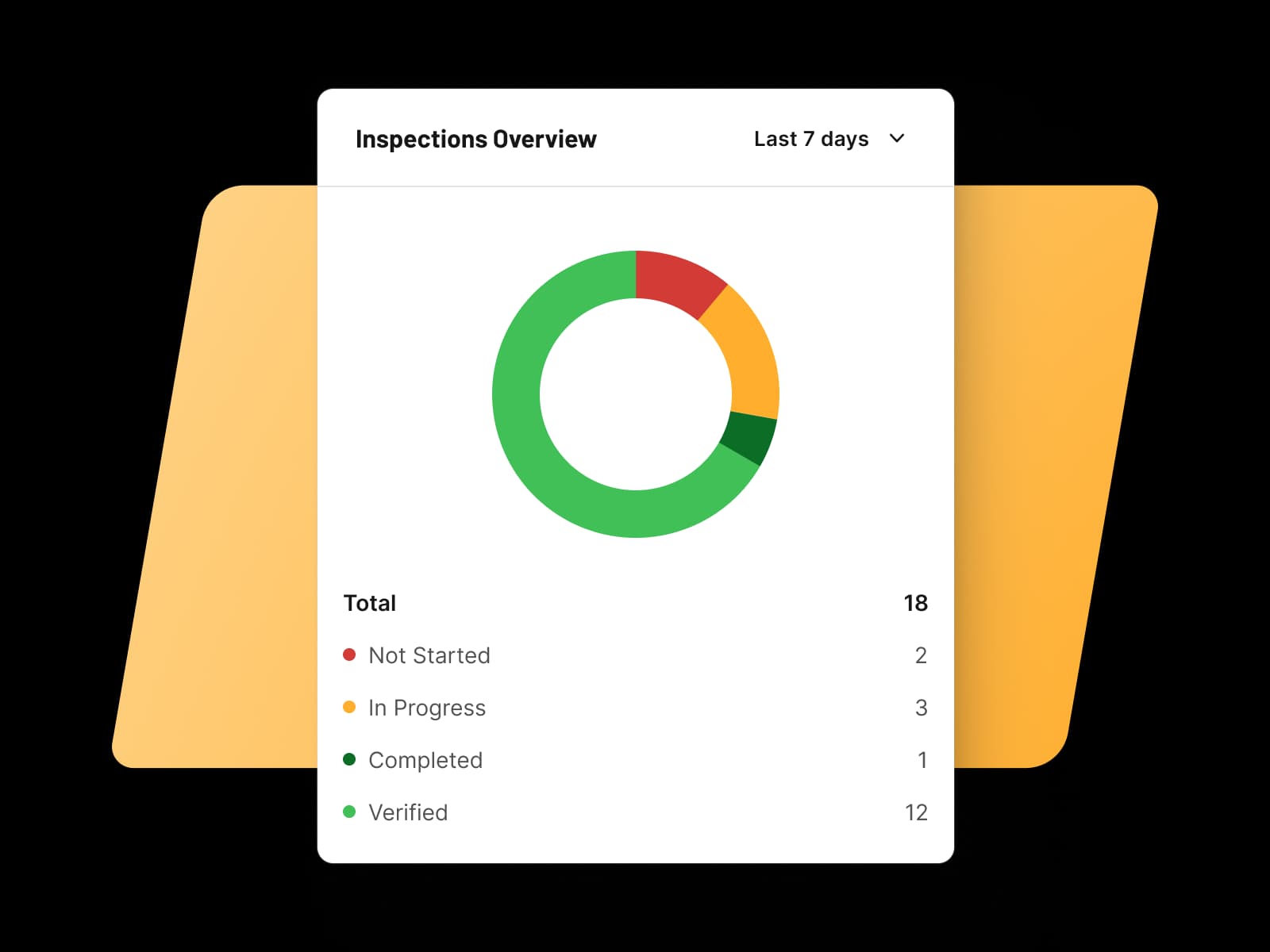

Access Everything from Your Dashboard

Inspections sync to your dashboard, giving teams real-time visibility into status. See which machines are complete, in-progress, or flagged. Export PDF reports with photos and signatures. Track recurring issues to spot trends. Search historical records by serial number or date. Monitor completion times and control data access.

Real Results from Machinery Manufacturers

See how Komplet transformed their inspection process

Komplet's Saved Thousands of Dollars Annually

Achieved by Komplet starting in 2024 after implementing Inspect across their production facility.

1-2 Hours Saved

Per machine on data entry100% Real-Time Visibility

Across the entire factoryInstant Record Retrieval

Find any inspection in secondsBuilt for Factory Floors.

Designed for Real Conditions.

Inspect includes everything machinery OEMs need to run quality inspections in demanding industrial environments.

AI-Powered Smart Scan

True Offline Mode

Evidence Built-In

Real-Time Dashboard & Reporting

Technician Friendly Interface

Voice Input & Location Tracking

Calculate Your Savings with Digital Inspections

See exactly how much your operation could save by replacing paper checklists. Most machinery OEMs save $86,500+ annually. Adjust the inputs below to match your operation.

Your Potential Annual Savings

per year

Payback Period: Less than 1 month

You also gain

Want a detailed breakdown customized for your operation?

Replace Paper with

Digital Confidence

Join machinery OEMs who've eliminated $86,500 in annual costs while gaining complete visibility into every inspection across their operation.