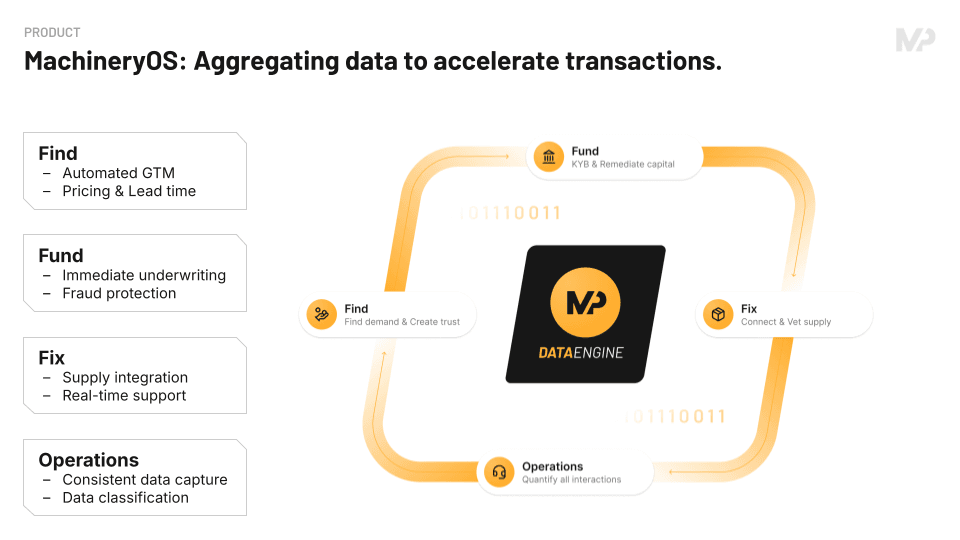

MachineryOS, the AI operating system for the equipment economy.

You’ll find below the description of all the technology we use to be the most responsive equipment platform and distributors in North America

1. The Future of the Equipment World is Digital

The world relies on machines to do big jobs (rock crushers, screeners, batch plants, shredders, and so many more) across construction, agriculture, and manufacturing.

Yet, how these machines are made, sold, financed, and serviced hasn’t evolved in decades.

For most companies (except giants like CAT or John Deere), demand volatility limits investments in innovation.

Machinery Partner bridges the gap between analog heavy equipment and modern digital tools.

From the first marketplace click to the last bolt tightened, every step is tracked, automated, and optimized with data.

We call it MachineryOS, the operating system for heavy equipment.

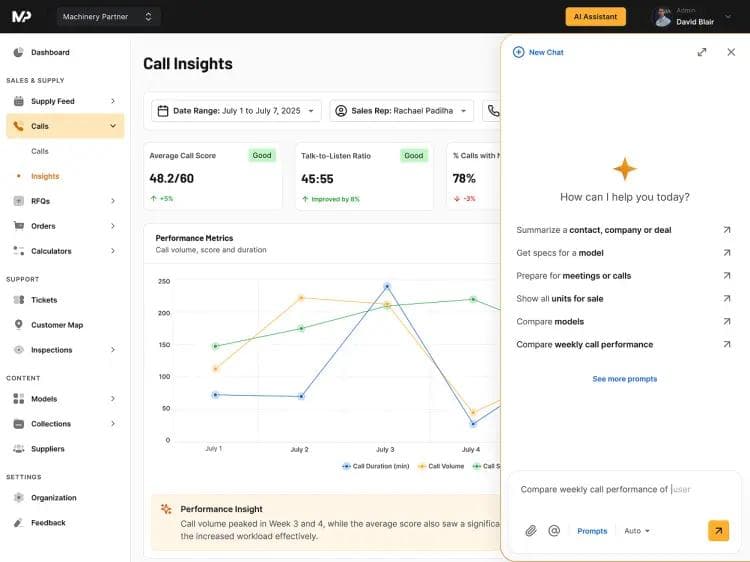

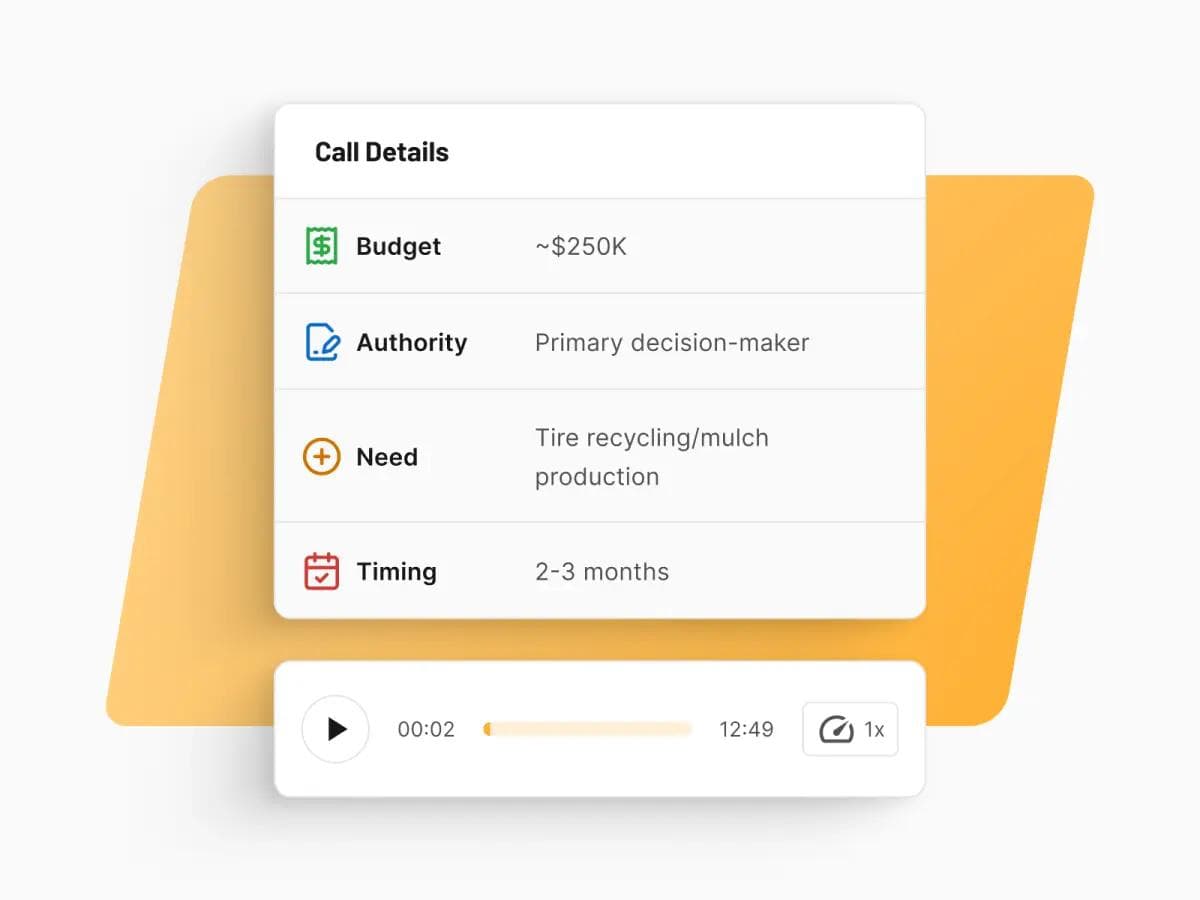

2. What We’ve Built: AI-powered commerce to answer Demand Planning

Our platform connects industrial clients and manufacturers based on real needs and availability.

AI enhances expertise, ensures transparent pricing, and optimizes on-the-ground support.

Every transaction trains models to forecast demand, predict downtime, and uncover new sales for OEMs and dealers.

“This partnership with Machinery Partner allows us to better support customers with faster parts availability, technical assistance, and a higher level of service responsiveness”

Andrew Kim, Hyundai Doosan Infracore

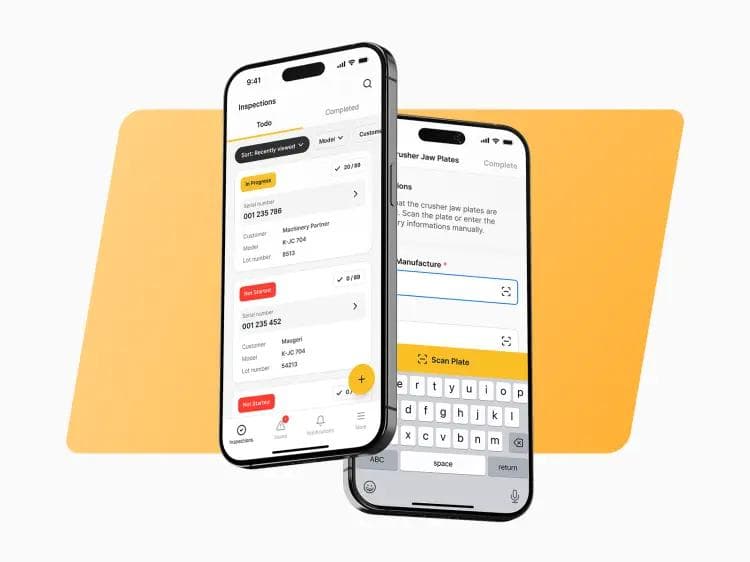

The Inspection App

Quality control once lived on clipboards; now it’s digital, tracking every machine from manufacturing to the end user.

Every machine passes through a digital inspection workflow.

Photos, diagnostics, and compliance reports are timestamped and shared in real time.

We've been looking for an automation solution like this for a couple of years now. The current paper-based process is a real drag on the business. What you've built is exactly what we need.

Caine Johnston Technical Support Engineer, Nordmann Equipment

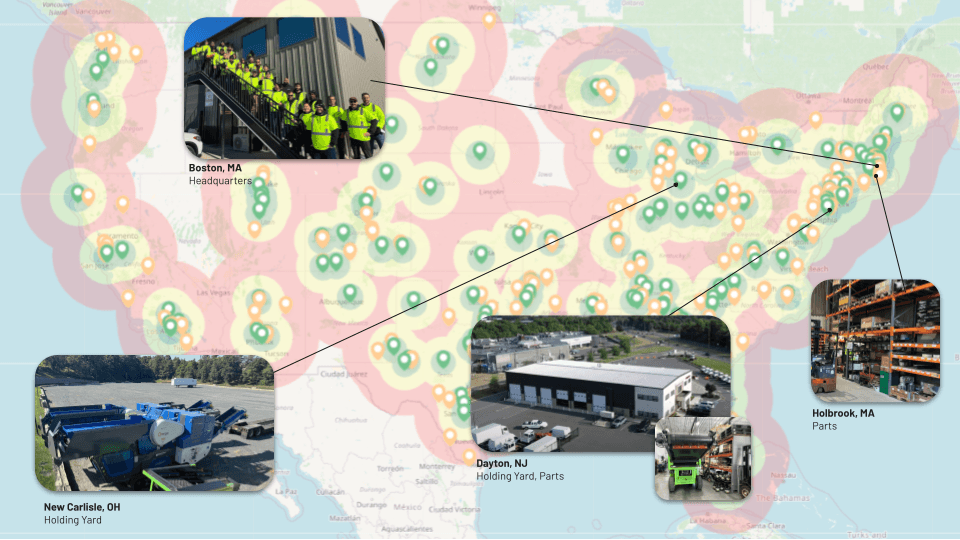

MP360 - Nationwide Service Network

150 certified technicians. 46 states. Combining digital scale with physical infrastructure.

Each visit enriches our data engine with part usage, service patterns, and environmental metrics, helping manufacturers improve design and reliability while supporting users.

Trusted by tier 1 OEMs like Terex, Astec, Metso and Hyundai Doosan Infracore.

MP360 is proving to be a reliable structure for all our partners.

Embedded Financing

Our AI underwriting engine reduces days of paperwork to minutes, pre-screening 90% of financing needs with just a company name, city, and state.

We’ve facilitated over $40M in equipment loans through Machinery Partner Capital Solutions.

We’re proud to support a financing experience that’s fast, flexible, and built around how modern contractors actually operate.

John Pfister, CEO MAZO Capital Solutions

3. Why This Matters Now

The physical economy is being rewired.

Factories, farms, and job sites are moving from manual to measurable.

Machinery Partner bridges the $580B equipment industry's gap in digitizing machines, financing, and aftermarket service.

4. What It Means for Our Partners

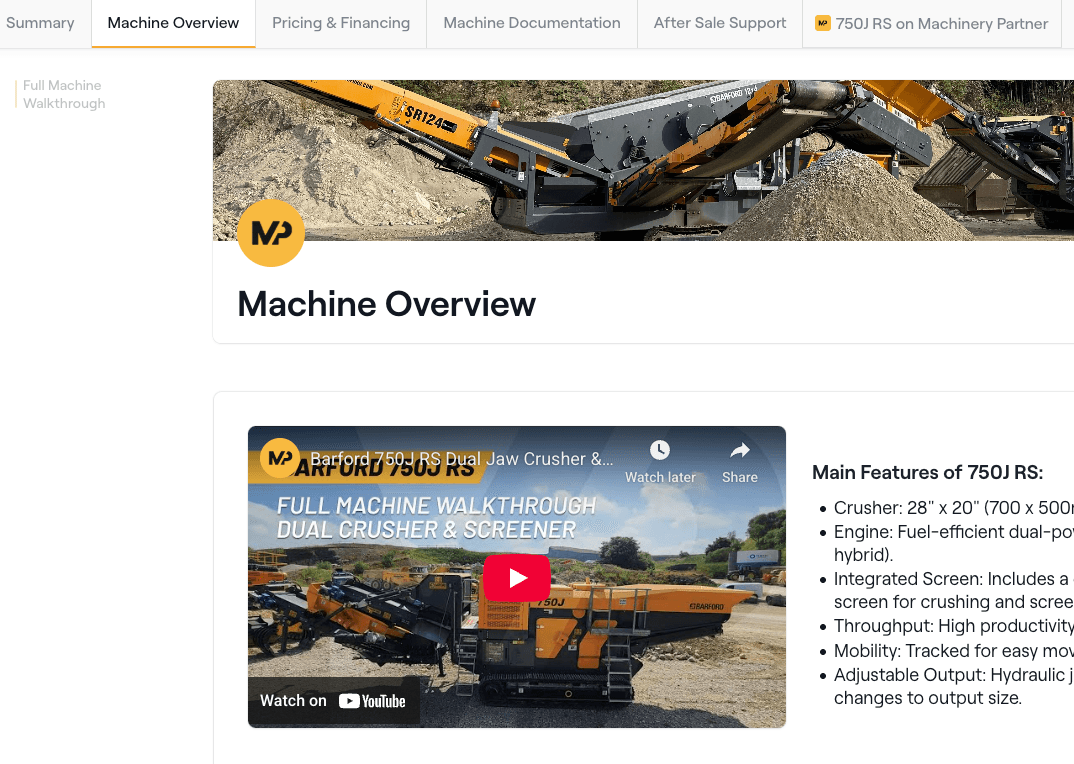

For Manufacturers and Dealers

You can sell anywhere without new branches.

Your brand thrives on our white-label marketplace with tech, financing, and service support.

Inspection, financing, and repair data return as actionable insights.

Barford has quickly grown its reach in the US thanks to Machinery Partner. Machinery Partner helped Barford reach new territories. They give provide technology solutions to help us reach more customers.

Stephen Murphy, Director of Sales at Barford Equipment

For our Client. Put everything in perspective

You get the right machine, faster and cheaper, by comparing all key specs and information.

Track delivery, access service history, and finance projects, all from one login in their private space.

For the Industry. Run RFQs to understand all the options

Gain visibility by running procurement and quoting systems for equipment.

For the first time, the physical world is measurable, predictable, and improvable.

5. What’s Next

Our mission remains: make equipment ownership as simple as ordering online.

With MachineryOS, AI powers every stage of the heavy equipment lifecycle: discovery, financing, delivery, and most importantly maintenance.

We’re building the digital backbone for America’s builders.

- Clement, David and all the Product team at Machinery Partner