How to choose the right Topsoil Screener

Topsoil screening can be a great source of income, especially if you are transporting material away from a site to dump or have access to free soil to screen. You are essentially making money from dirt!

If you’re moving a lot of dirt or compost, a topsoil screener helps you turn piles of raw material into sellable product. But not every screener is built for the same job size, volume, or material type. This guide breaks down the main types of topsoil screeners, how they work, and which models fit specific contractor needs, from backyard jobs to 100,000+ yard sites.

In this post, we’re going to go through some of the screener options out there and which ones might be right for topsoil. We'll also give you an idea of budget and output so you can decide what the best option is for you if you're trying to get into topsoil screening.

What is Topsoil?

Topsoil is the soil that makes up the top 2 to 12 inches of ground, depending on the area. It's full of broken-down organic material from leaves, dead animals, and vegetation and makes a huge difference to how plants grow because it's full of nutrients. This also means it's much darker in color than other types of soil.

Why do I need to screen topsoil?

Other than this organic soil material, topsoil is also made up of a mix of rocks, water, contaminants, and other organic materials like plant roots, sticks, and weeds. In its raw state like this, it isn't very useful because these rocks and sticks will hold back the roots of new plants from sprouting and can restrict water flow. If topsoil is screened to remove larger rocks and things like sticks or roots, it can be very useful for gardening and other applications where plant growth is promoted. It is also generally worth a lot more after it has been screened, which is what we’re interested in! Generally speaking, the finer the product, the more expensive it is.

What does a topsoil screener do?

- Removes rocks, roots, and debris

- Turns raw dirt into high-quality topsoil

- Saves time on-site vs. hand screening

- Turns waste into revenue

Types of topsoil screeners

Now there are a bunch of different types of screens out there, but for topsoil, we're only interested in screens that can output a product in and around the 1/2 inch or 10mm size. Once we break it down into categories of screeners that can produce this size of material, you have six basic options:

- Fines screeners

- Scalping screens

- Star screens

- Trommel screens

- Screening decks

- Screening boxes

- Screening buckets

What machine you choose from here will depend on a few things, like how much screening you want to do, whether you need a unit that is easy to transport or store, and how much you want to spend! You should try to estimate how much time you plan to spend screening soil; there's no point buying a machine that is too big or too small for your needs. You'll also need to consider the supply and demand of topsoil in your area.

Chances are you won't have an unlimited amount of topsoil around you to process, and even if you do, you need to make sure there are enough people around you that want to buy screened topsoil. Once you've figured out how much time you have to screen and how much material you plan to process, you can take a look at different screen types and models. We go into a lot more detail on tonnage per hour in our post on screening topsoil, but roughly speaking, excavator buckets and screen boxes will do sub 50 tons/hour. Anything over that and you're going to need a larger dedicated screening machine like a trommel or a star screener.

Trommel Screeners

Trommel screeners use a rotating drum with holes to separate fine material from oversized debris. As the drum spins, dirt, compost, mulch, or topsoil gets tumbled and sifted. Finer material falls through the screen while larger chunks roll out the back.

Why choose a trommel screener?

Trommels are ideal when you’re working with:

- Wet or clumpy topsoil

- Compost with sticks and organic matter

- Mixed materials that need to be sorted into multiple sizes

They’re especially useful for contractors and materials yards producing topsoil, mulch, compost, or screened fill on a regular basis.

Key advantages of a trommel screener:

- Less clogging: Handles moisture and stickier material better than deck screeners

- Higher product quality: Produces a cleaner, more consistent finished product

- Multiple product sizes: Most trommels can separate material into 2 or 3 output sizes in one pass

- Easy to operate: Feed in material with a loader and let the drum do the work

Trommel example; Barford T620

- High-capacity option: up to 300 tph

- Cuts screening time in half vs. smaller models

- Better for large composting operations or bulk material suppliers

- Long-term cost per ton: $1.28 (based on 1,000 hrs use)

Screening buckets

If you already have an excavator, a screening bucket might be a great option.

There are some fairly cheap options, like this Italdem GV150, or CM CBR bucket screener that can be used on a site to sort material into two products pretty quickly. They also reduce the need to transport stuff to and from a job.

Screen boxes

Screen boxes are also a fantastic option where you want to process more material, but budget is a limiting factor.

Once you go over that 50 tons/hour mark, you can't use a screen box or screening bucket and will need to invest in a larger screening machine.

Larger units will significantly up the amount of topsoil screening you can do and have the potential to make you a lot of money per hour.

But they also cost a lot more upfront, getting into the $100ks and sometimes over $1 million.

One of the nice things about buying a larger screen is that there is usually a lot of demand for them, so you can rent it out to recoup some of the cost of financing the machine.

If you buy something like a tracked scalping screen that can process a variety of materials, you can probably claw back the cost of financing your machine by renting it out for a week a month.

Scalping screens

When looking at larger screening plants, we usually recommend either a scalping screen or a fine screen.

Scalping screens are very versatile machines and can handle a range of materials, from demolition waste to fine topsoil.

They work on a decline and can be set up to intake or output a variety of material sizes depending on the need.

They can't make a super fine topsoil product, but if you want to use your screener for a range of jobs or want to rent it out, they're hard to pass.

Star screens

Star Screeners are made up of hundreds of 'stars' that rotate rapidly. The stars control the size of the material or topsoil that can sit through the deck, meaning that you can easily sift out oversize materials from the precious topsoil. Star screeners are the ideal solution for companies that need to sift and process topsoil in bulk.

These machines are costly but deliver the best output, making sure customers get exactly the type of soil they're after. Star screeners are perfect for companies that are processing large amounts of material that other machinery simply won't be able to handle. With their state-of-the-art function and reliable performance, star screeners provide a lot of bang for your buck when it comes to sifting and making topsoil. So if you have a business that requires handling large amounts of topsoil, look no further—a star screener is just the machine you need!

Check out the video below to find out all you need to know about star screeners, how they work, and how they are great for screening and making topsoil.

Fine screens

As the name suggests, fine screens make a finer product.

They work with a screening deck that is on an incline, generally producing a product in the 1-6mm range.

But it’s also worth noting that you can’t dump large rocks and stones into these machines as they will likely damage the fine mesh.

If you’re looking to invest in some equipment to screen topsoil, Machinery Partner is always here to provide free and unbiased advice on what machine might be right for you.

We have over 15 years of experience with crushing and screening and no allegiances to one manufacturer or product, so we always put your needs first.

Give us a call or send us an email, and we’ll be more than happy to help you start your journey into topsoil screening!

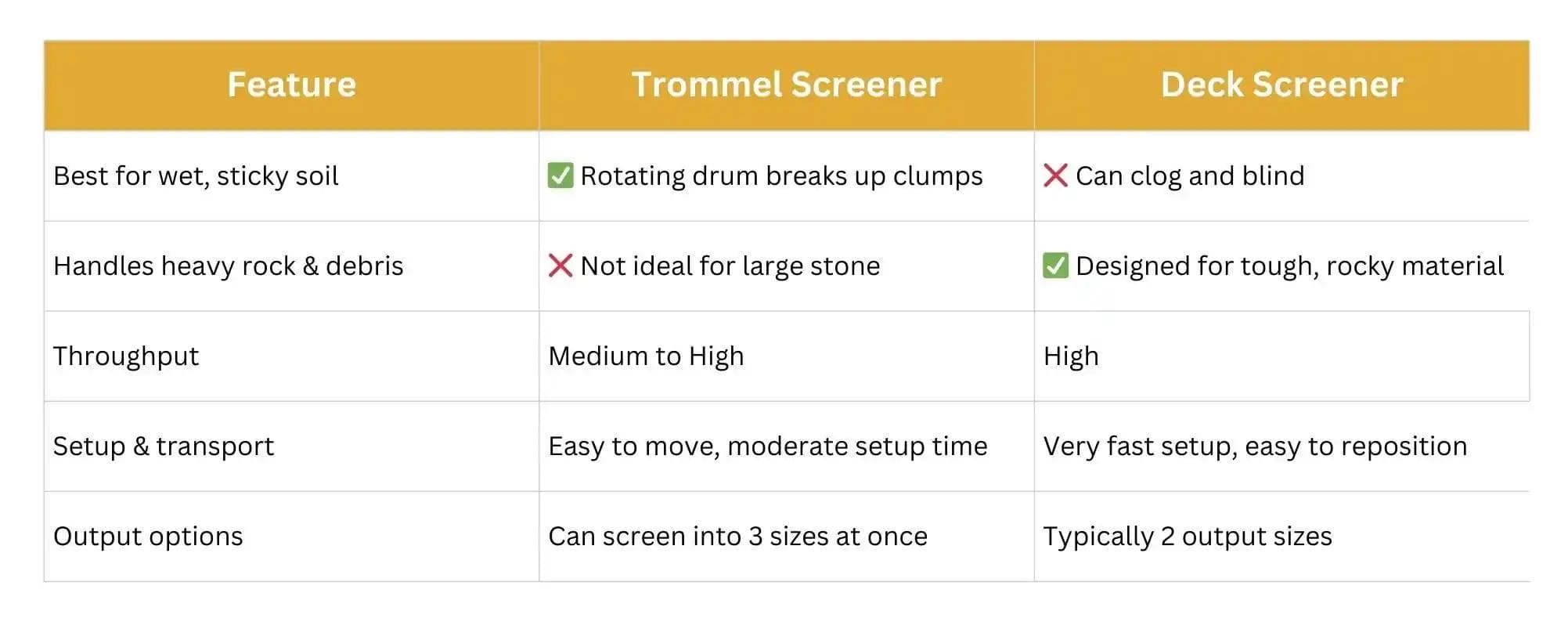

Trommel vs Deck Screen for Topsoil

When choosing a topsoil screener, the first decision is between a trommel screener and a deck (or scalping) screener. They handle materials differently, and each works best in different conditions.

Quick tip:

If you’re working with compost or damp topsoil, go with a trommel. If you’re screening gravel-heavy mixes or dry material, a deck screener will perform better and faster.

Help from the experts

Find topsoil screeners for sale. Not sure which machine is the best one for your business? Don't worry - Machinery Partner experts are always here to help! For more information on everything from star screeners to screening buckets give us a call.

Machinery Partner also has a full range of screening equipment sourced directly from the manufacturer - cutting out the middleman and saving you money!