DPF Regen Explained: Why It Matters for Your Diesel Machine | Avoid Downtime

If you run diesel-powered equipment, you need to understand how regen works.Whether you operate a crusher, screener, or other heavy machinery, diesel engines with emissions systems rely on a process called regeneration. Skipping it can shut your machine down and cost you time and money.

This guide explains what regen is, when to do it, and why it matters for your equipment’s performance and uptime.

What Is Regen?

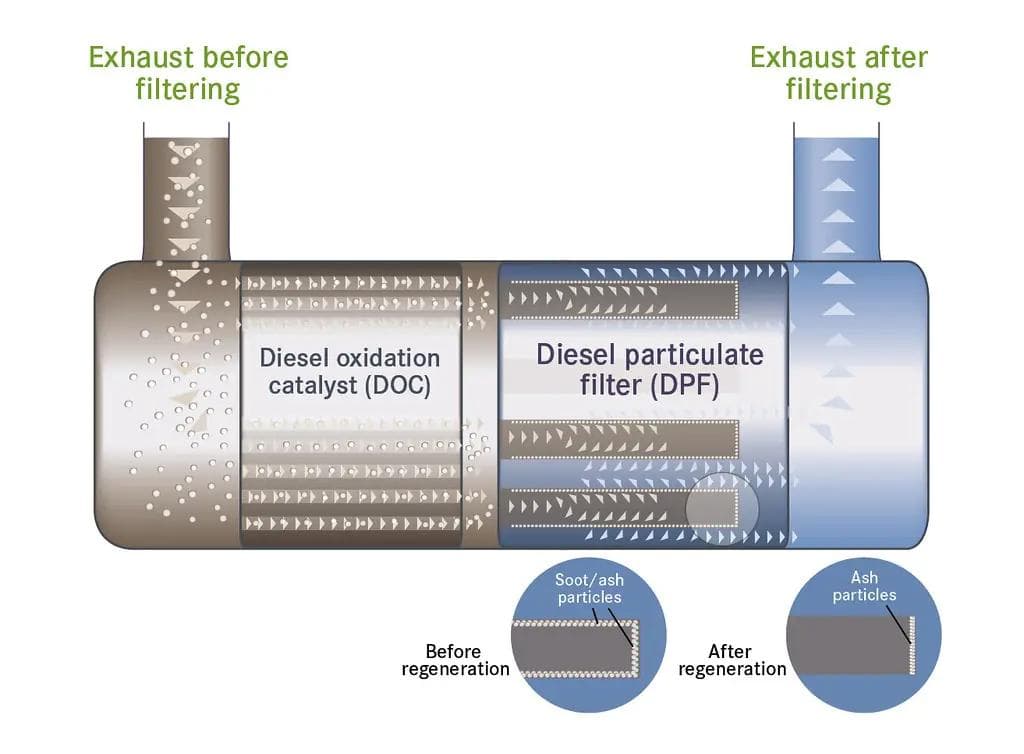

Regen is short for regeneration. It is the process your engine uses to clean out the Diesel Particulate Filter (DPF). The DPF traps soot and other contaminants from your exhaust system to keep your machine running clean and compliant with emissions laws.

Over time, soot builds up in the filter. Your machine needs to burn it off to stay running properly. That is what regen does. It heats the DPF to a high temperature and burns away the buildup so the filter stays clear.

Why Your Diesel Machine Needs to Regen

If you skip regen, the soot keeps collecting. This clogs the DPF and causes problems. Most machines will eventually go into derate mode. That means your engine will limit its own power to prevent damage. Some engines will shut down completely and require a technician visit to unlock.

Missed regens can lead to:

- Lost production hours

- Costly field service calls

- Permanent engine damage in extreme cases

Regen keeps your emissions system clean. That protects your machine and helps avoid downtime.

How to Know When to Regen

Most modern diesel machines will alert you when it is time. Look for a regen symbol or warning light on your display screen.

You may also notice signs like:

- Reduced power

- High idle that does not go away

- Higher fuel usage

- Alerts related to exhaust or emissions

Your machine can, it may attempt an automatic regen during use. But if conditions are not right, it will not complete. This is common on machines that idle a lot or do short jobs.

How to Perform a Manual Regen

If your machine cannot auto-regen, you need to run a manual cycle. Here is how to do it safely and correctly:

- Let the engine reach operating temperature

- Make sure no other functions are active

- Park the machine and allow it to idle

- Use your regen switch or control panel to start the process

- Let the cycle run until complete

A regen takes 20 to 45 minutes on most machines. You will hear the engine rev up when the cycle begins. It will return to idle when finished.

Do not shut down the machine during regen or try to use it while the cycle is active.

Regen Process on Barford Machines

If you are running a Barford 750J or 750J RS with a Caterpillar engine, here is how to run a manual regen. This process comes straight from Doug on our support team.

Steps for a successful regen:

- Turn on the battery disconnect

- Start the engine and let it idle

- Open the side panel to access the control unit

- Flip the regen rocker switch

- Wait for the machine to take the regen and complete the cycle

You can watch Doug explain this process step by step in the video at the start of this post!

Regen Tips for Small Contractors

- Run a manual regen at the end of each day, especially if your machine idled a lot

- Keep an eye on soot levels through your machine’s screen

- Never ignore a regen alert

- Schedule time for regen so it does not interrupt your job

FAQ: Regen and DPF Maintenance

What happens if I ignore a regen alert?

The engine will first derate, then shut down. A tech visit from the engine manufacturer will be needed to reset it.

Can I use my crusher while it is doing a regen?

No. The engine must be idling with no load. Do not crush, screen, or move the machine during regen.

How long does a regen take?

Most regen cycles last between 20 and 45 minutes depending on soot levels.

How can I tell if a regen is working?

You will hear the engine rev higher and see signs on your control panel. Once the process finishes, the machine will idle back down.

Need Help With Regen?

If your machine won’t regen, gets stuck in derate, or you are not sure what to do next, call the Machinery Partner Service and Support team. We help customers troubleshoot these issues every day.

Contact us at 888-297-0623 or email service@machinerypartner.com - We’ll walk you through it and help get your machine back to work.