What is a grader?

Article updated October 16, 2025

What is a motor grader?

A grader, most commonly known as a motor grader or road grader, is a multi-purpose earthmoving machine that is used not only in construction sites to create flat smoother surfaces in road building projects but also in the mining/quarry industry for mining underneath the ground surface. They are uniquely structured and are primarily characterized by a long, large, and adjustable blade between the front and rear twin wheels.

Contractors choose a grader machine when they need precise grading, tight tolerances, and a smooth finish grade over long distances where a bulldozer or backhoe would be less efficient. Modern road graders pair high engine power with fine hydraulic controls to strike off material, crown gravel roads, and cut drainage ditches with speed and accuracy.

Due to the many uses attributed to this equipment and its precision in producing quality surface finishes within the shortest time possible, the rate of demand for graders has significantly increased over the last few years, and for this reason, it is therefore deemed to be absolutely necessary equipment in any construction site.

You will see motor graders across the construction industry on subdivision pads, airport runways, wind farms, and mine haul roads, where durability, low operating costs, and fast cycle times matter.

Key features you need to know about motor graders!

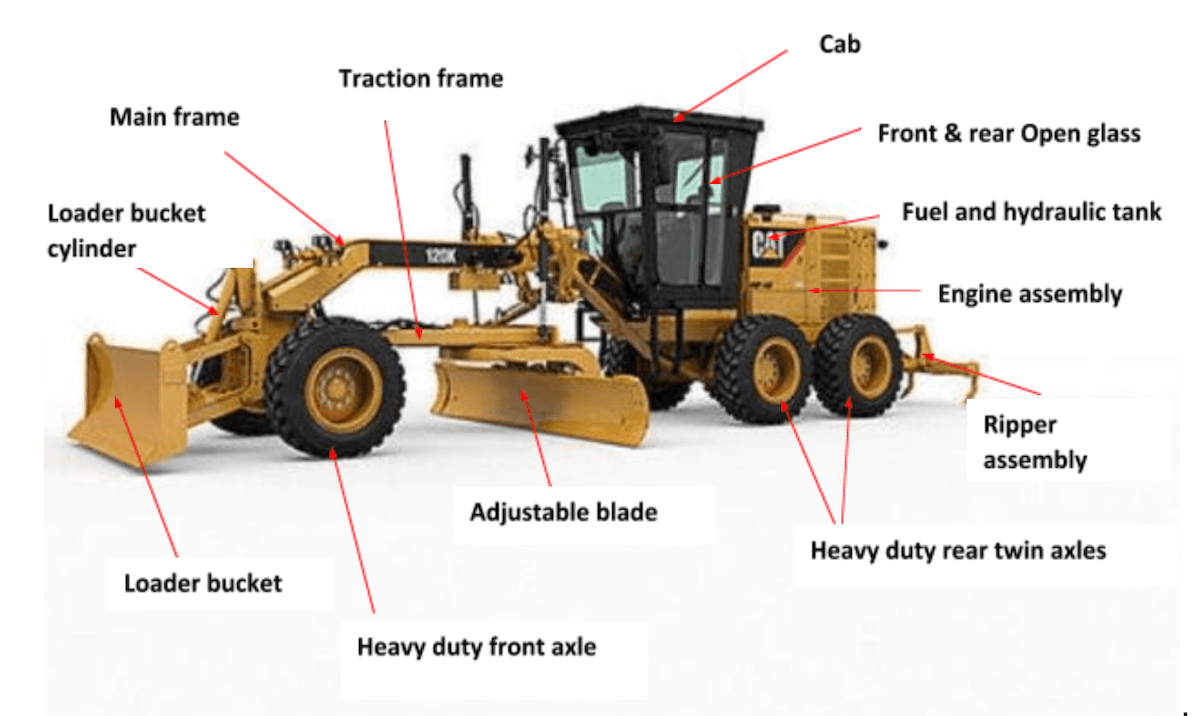

A typical common motor grader has three axles (front and rear twin axles), an engine, a cab, and an adjustable blade. However, most modern motor graders do have either a ripper, a scarifier, a loader bucket (or both), and a compactor attached to the front and rear axles, respectively. This brings about an added advantage, as such equipment could perform multiple purposes within a short period of time.

Look for heavy-duty front axle oscillation, multi-wheel drive options (AWD on front wheels), tight turning radius via articulation, and auto-shift transmissions that reduce operator fatigue. Grade control packages with 2D cross slope or 3D GNSS can automate moldboard position for consistent results.

The main function of the adjustable blade is to cut through uneven surfaces and produce the desired surface finish. The blades are normally fitted under the traction frame with rings that spin vertically so as to adjust the angle of the blade to any required specifications. For this reason, graders can also be used in terrains with vertical profiles, such as ditches and banks.

The blade and moldboard geometry are critical. Properly setting blade pitch, circle side-shift, and moldboard angle improves material roll and reduces horsepower draw, which lowers fuel burn. For finish grading on base course, operators often run a slight positive pitch with the cutting edge just kissing the surface. See finish grading tips (/blog/finish-grading-best-practices).

Also, the blades are always well sharpened to ease their penetration through the soil and are also placed in a good position for the motor graders to perform more efficiently. They are also long, structured, and large so as to provide a large span of movement and cover a wider scope of work.

Use the correct cutting edge system for your material: standard through-hardened edges for general earthmoving, wear-resistant carbide-insert edges for high-abrasion gravel maintenance, and serrated edges for scarifying compacted surfaces before reshaping.

The cab is a protective casing to prevent the operators from being subjected to adverse environmental conditions. It’s also transparent to provide great visibility to the operator. It has a front and rear open glass to allow for free circulation of air.

Premium cabs add joystick steering, low-effort electrohydraulics, heated air-suspension seats, and high-visibility sloped hoods. Many OEMs integrate a steering wheel plus joystick choice so operators can pick the control style that suits the jobsite.

The scarifier is usually used when breaking or tearing up an already existing pavement during its maintenance phase and can also be used when the road surface is very hard for the grader blade to cut through. If the motor grader used does not have the scarifier, then an excavator loader bucket can be used to break the hard surface using its teeth. Therefore, a motor grader with a scarifier is very essential when reconstructing pavements or in areas with extremely hard road surfaces.

A mid-mount scarifier with replaceable shanks speeds up reclaim work on chip-seal or compacted base. Pairing the grader with wheel loaders (/equipment/wheel-loaders) or excavators (/equipment/excavators) keeps material moving and minimizes idle time.

A ripper is an attachment fitted on the rear end of a motor grader. It has claw-like structures that are thick, hard, and pointed for the purpose of breaking up hard surfaces, asphalt, or loosening materials. This is achieved by continuous raising and lowering of the ripper claws. It is also used to rip open boulders, huge roots, and stumps for ease of their removal.

Choose three-shank or five-shank rippers based on operating weight and soil conditions. Heavier graders carry longer shanks for deeper cut in frost or caliche.

A loader bucket could also be attached to the front axle of a motor grader. It comes in handy during material handling, the removal of unwanted material or excess material, carrying of boulders, and transferring them from one point to another.

Some municipalities spec a front dozer blade instead of a bucket for winter snow removal and windrow management. Quick-attach systems let crews swap tools fast between seasons.

What can you do with a motor grader?

Motor graders are used to perform a wide range of activities, mostly in the following areas: in civil engineering projects to carry out fine grading; in the mining industry; in foundation works of large structural buildings; in spreading and earth moving; and also in snow removal.

Common tasks include cutting crown and cross slope, mixing and spreading aggregate, maintaining haul roads for fewer truck delays, trimming subgrade to laser or GPS, and building V-ditches for drainage.

Motor graders were originally used in the construction of unpaved roads such as dirt roads and gravel roads to level up the underlying terrain so as to produce flat and smoother surfaces and also carry small quantities of material from one place to another. Up to now, graders are still being used in rural areas in the construction of low-volume earth roads.

On gravel roads, plan routine passes to pull material from shoulders, break washboards, and re-establish crown. Proper crown sheds water and extends road life.

Secondly, they are used during either the construction or maintenance of paved roads to prepare the uppermost layer by creating a flat surface for the laying of asphalt on it.

Before paving, the grader trims to final elevation, leaving a uniform mat that reduces the number of roller passes needed by the compactor fleet.

Thirdly, motor graders make sure that the rollers/compactors are effectively used, bearing the minimum load on them. Also, motor graders are used in snowy areas for the removal of snow and debris and later moving them from one place to another.

For winter ops, spec AWD front wheel drive, high-output lighting, and a snow wing for faster lane clearing.

They are also used during the foundation works of a certain project in setting the natural soil to the required level before the construction of large buildings. Consequently, graders can be used in the mixing of two or more materials in any construction site.

With automated grade control, precise grading tolerances of ±3–6 mm are routine, which reduces rework for follow-on trades.

Motor graders with a scarifier enable the removal of the top layer of previously wrecked pavements damaged by heavy traffic and then spreading/resurfacing it with a new layer of either gravel, aggregates, or asphalt and polishing it up.

On full-depth reclamation projects, a grader often works ahead of a recycler to pre-rip and blend materials, then comes back to strike off for compaction.

Lastly, in the mining sites, graders can either be fitted with multiple attachments or are designed to perform specialized mining tasks.

In the mining industry, graders maintain ramps and intersections so haul trucks run at target speeds, cutting fuel and tire wear. The result is lower operating costs across the pit.

The various brands of graders

Over the last century, there have been at least three leading brands that have significantly improved their graders to meet the huge demands arising in the construction industry. This has given them an upper hand; thus, they are the most recognized and highly regarded brands due to their incredible features.

Popular models span a wide operating weight range, from compact 12–14 ton graders for tight jobsites to heavy 20–25 ton machines for highway and quarry work.

The frequently asked question is, does it really matter what grader brand you use? The grader brand does not matter; what matters is the specific operation you want from the grader brand. Having known that, pick the brand with the most satisfying operational features.

Key spec checkpoints: moldboard width and height, net horsepower, AWD availability, articulation angle, circle drive protection, tire size, and factory grade-control readiness.

Below are the top most motor grader brands and their key features:

Caterpillar (CAT) Graders

The cat industry is the giant when it comes to the construction equipment machinery. They have been in the industry for quite some years, approximately over 40 years before other brands came in. For this reason, they are more preferred and chosen by quite a number of people. The key features of cat graders are listed below:

Caterpillar offers cross slope with integrated sensors, stable blade technology, and auto-articulation for tight spaces. Cat’s joystick controls are known for smooth metering and precise grading. Dealer parts networks help minimize downtime.

The steering is auto-articulated, giving the operator better performance in tight spaces. This brings about improved productivity and reduced operator fatigue.

The new series on the market can detect any bounce effect and stabilize itself within a span of 15% speed adjustments.

The cross-slope provides more precise accuracy levels and provides adequate control over the grader. It also has automated pitch adjustments for more precise grading.

John Deere Graders

These types of brands have dominated over the agricultural sector; however, this doesn’t mean that they are not regarded more in the construction industry. Why choose John Deere Graders? Here are some of its key features:

John Deere graders feature Auto-Shift transmissions, intuitive joystick or steering wheel options, and grade-control integration. Deere’s SmartGrade packages enable mastless 3D control for clean visibility of the front end.

They have automated grader blade controls, which greatly improve the productivity of a job by reducing the amount of time taken significantly.

John Deere motor graders offer the most comfortable and smoothest power shift transmission, thus enabling an operator to work conveniently for longer durations.

Introduction of a pro system that uses a joystick steering wheel, therefore an operator is able to choose how to handle the work given.

Komatsu Graders

This is a Japanese brand, and being the second largest construction equipment manufacturer, it has gained a wide preference across the world. The key features of Komatsu graders include:

Komatsu emphasizes low-noise cabs, efficient hydraulics, and reliable circle drives. Many models support factory 2D cross-slope with upgrade paths to 3D GNSS.

They have reduced operator noise levels so as to provide a more comfortable working environment for the operator. They have ground-level refueling tanks for easy access and also fast fuel filling.

They have advanced and improved hydraulic systems that provide excellent blade movement and adequate blade pressure.

How are graders maintained?

Proper maintenance is very essential for the motor grader to continuously perform effectively and efficiently and also to its optimum capacity.

Daily: walkaround for leaks, loose hardware, cutting edge wear, tire condition, and lighting. Weekly: circle gear case oil level, articulation and drawbar pivots, and hydraulic filters. Track PM by hours to plan cutting edge and tire replacements before they become a productivity problem.

Most importantly, the grader blade fitted to the moldboard must have a good, sharp cutting edge. This increases the ease with which the blade cuts through the material. The degree with which the material is abrasive ultimately determines the rate at which the blade becomes worn out. Once the blade is worn out, it should be immediately replaced to avoid the moldboard from being at risk of wearing out too, leading to unnecessary replacements and hence further costs.

Rotate cutting edges and end bits on schedule to maximize life. Keep spare parts kits on the service truck to avoid lost shifts.

Also, the graders’ air filters should be occasionally checked to ensure that no dirt has accumulated in there. The presence of dirt clogs the air filters, thus reducing the efficiency of the graders and subsequently increasing the consumption of fuel. They therefore require the operators to constantly monitor them or introduce a pre-filter whose role is to reduce the amount of dirt particles entering the air filter. Use of pre-filters helps in reducing the number with which the operator would have to replace the air filter, hence saving on costs that would have otherwise been accrued.

Monitor engine air restriction indicators and replace filters when differential pressure is high, not simply by calendar time.

The teeth of the scarifiers or the rippers should be monitored and not allowed to wear out to the point where the scarifier shank is reached. If such happens, then both the scarifier and the scarifier shank have to be replaced, a more costly task than just replacing the scarifier teeth alone.

Keep extra ripper shanks and points on hand for rocky jobsites to prevent unplanned downtime.

The tire pressure is another essential element that has to be checked and monitored regularly because tire traction affects the graders’ grade precision. Consequently, the tire threads should be of the required specification so as to provide adequate grip with the ground surface to prevent skidding of the machine.

Correct tire pressures improve ride quality and moldboard stability, especially at higher travel speeds.

For overall operator comfort and safety, the floor mat, brakes, seatbelts, steering wheel, and handles should be regularly checked. The presence of loose handles and seatbelts makes the work more tedious and difficult to execute, leading to a lack of precision and prolonged working durations, reducing overall productivity.

Calibrate joystick and control responses after major service to keep machine feel consistent across operators.

Why are graders convenient for road construction?

In conclusion, motor graders execute a variety of activities in the construction sites; therefore, they are vital equipment in any site. Not only is it used to produce flat surfaces on unpaved roads but also create smooth surfaces in paved roads for the laying of asphalt.

They bridge the gap between dozers and compactors, delivering precise grading at production rates that keep paving trains and liner crews on schedule.

They are also convenient in the construction of roads along terrains with vertical profiles or curvatures using their adjustable blades, producing surface finishes with the desired specifications.

Articulation plus front wheel lean helps the operator track around curves while keeping the moldboard square to the cut.

Graders can also be used in constructing/creating ditches for drainage purposes or curing bank canals. Its adjustable blade is of advantage as it can be adjusted to any desired angle, creating the required ditch or bank outlook.

Set cross slope correctly and pull a clean V-ditch to move water off the roadway fast, extending base life and reducing potholes.

In reconstruction of existing pavements that are wrecked due to damages from excessive heavy traffic, graders’ rippers/scarifiers can be used to break the asphalt, and then the grader lays a new material such as gravel or new asphalt on the pavement.

Understanding Motor Graders

A motor grader, also known as a road grader, is a versatile earthmoving machine. It's primarily used in construction sites to create flat, smooth surfaces in road building projects. Additionally, it's utilized in the mining/quarry industry for mining underneath the ground surface.

On utility jobsites, smaller six-wheel graders trim trench backfill and restore crown without mobilizing larger heavy equipment.

Motor graders are characterized by a long, large, and adjustable blade between the front and rear twin wheels. Their precision in producing quality surface finishes quickly has led to a significant increase in demand over the last few years.

Spec AWD for snow removal districts and steep grades; stick with rear-wheel drive for flat, dry jobs where fuel efficiency is the priority.

Match operating weight and moldboard width to the work: 12–13 ft boards are common for municipal work; 14–16 ft for highway and mine haul roads.

Key Features of Motor Graders

A typical motor grader has three axles, an engine, a cab, and an adjustable blade. Modern motor graders may also have a ripper, a scarifier, a loader bucket, and a compactor attached to the front and rear axles. These additional features allow the equipment to perform multiple tasks within a short period.

- Adjustable Blade: The main function of the adjustable blade is to cut through uneven surfaces and produce the desired surface finish. The blades are well sharpened, long, and large to provide a wide range of movement and cover a wider scope of work.

- Cab: The cab is a protective casing that shields the operators from adverse environmental conditions. It's transparent to provide great visibility to the operator.

- Scarifier: The scarifier is used when breaking up an existing pavement during its maintenance phase. It's essential when reconstructing pavements or in areas with extremely hard road surfaces.

- Ripper: A ripper is an attachment fitted on the rear end of a motor grader. It's used to break up hard surfaces, asphalt, or loosening materials.

- Loader Bucket: A loader bucket could also be attached to the front axle of a motor grader. It's useful during material handling and the removal of unwanted or excess material.

Applications of Motor Graders

Motor graders are used in a wide range of activities, including civil engineering projects, mining industry, foundation works of large structural buildings, spreading and earth moving, and snow removal. They are also used during the foundation works of a project in setting the natural soil to the required level before the construction of large buildings.

They also support pipeline spreads, solar farm grading, and platform pad construction where long, flat surface requirements dominate.

Top Motor Grader Brands

There are several brands of motor graders, but three have significantly improved their graders to meet the huge demands arising in the construction industry. These include Caterpillar (CAT) Graders, John Deere Graders, and Komatsu Graders. Each brand has its unique features that make it stand out.

Other players include Case, Volvo CE, Sany, and XCMG, each with unique joystick layouts, hydraulic feel, and dealer support footprints.

Maintenance of Graders

Proper maintenance is essential for the motor grader to perform effectively and efficiently. This includes regular checks on the grader blade, air filters, scarifier or ripper teeth, and tire pressure.

Set up a preventative maintenance calendar and log hours by task so you can forecast wear-part consumption and budget accurately.

Why Graders are Convenient for Road Construction

Motor graders execute a variety of activities in construction sites, making them vital equipment. They are used to produce flat surfaces on unpaved roads, create smooth surfaces in paved roads for the laying of asphalt, and construct roads along terrains with vertical profiles or curvatures.

Because graders deliver a superior flat surface with fewer passes, they lower aggregate, fuel, and labor per lane-mile compared to less precise methods.

In conclusion, motor graders are an essential piece of equipment in any construction site due to their versatility and precision in producing quality surface finishes.

Need help sizing the right grader for your jobsite and budget? The Machinery Partner team is ready to help!