Stone Crushing: A Guide to Rock Crushing Machines

Article updated October 15, 2025

Crushing stone is a straightforward process when you have the right equipment. Whether you're a contractor looking to repurpose on-site materials or a business aiming to produce aggregate for resale, understanding the basics of stone crushing can open up new revenue streams and reduce waste.

The modern stone crushing process uses heavy-duty machines like jaw crushers, impact crushers, and cone crushers to break down raw materials into usable aggregate. With the right setup, you can process hard materials like granite, basalt, or limestone efficiently while producing consistent, high-quality output.

Are you tired of hauling piles of waste stone to the landfill? It might be time to consider turning those piles into a new revenue for you and your business. Crushed stone is in demand as it has so many uses. Depending on the size and type of crushed stone, different industries have different needs. These range from clean stone used as top layers of driveways all the way to road base in paving projects.

Stone crushing machines help you reduce large rocks into smaller pieces suitable for construction, landscaping, or infrastructure projects. By creating your own crushed stone on-site, you eliminate disposal costs and transportation fees, making your operation more sustainable and profitable.

How to crush large rocks into smaller stones

To crush stone, you will firstly need a constant supply of large rocks. You might already be lucky and have loads at your job site! Some common rock examples are granite, caliche, and limestone. Small batches of soft rocks such as sandstone and caliche can be roughly broken up by a hydraulic breaker attached to an excavator. If the rocks are harder (granite and basalt) they will require more crushing power. A compact jaw crusher will be necessary for this job. If your goal is to crush natural stone, consider investing in a larger mobile jaw crusher as these will give you a lot more crushing power to break down that hard rock.

The crushing process typically starts with primary crushing, where a jaw crusher breaks down large stones into manageable sizes. From there, secondary crushers—such as cone or impact crushers—further reduce material to specific gradations. For fine or tertiary crushing, specialized machines like hammermills or vertical shaft impactors (VSIs) can produce fine, uniform aggregate.

To improve production efficiency, most crushing setups use vibrating feeders and hoppers to regulate material flow, ensuring steady feed rates and preventing downtime caused by blockages.

What types of stone can you crush?

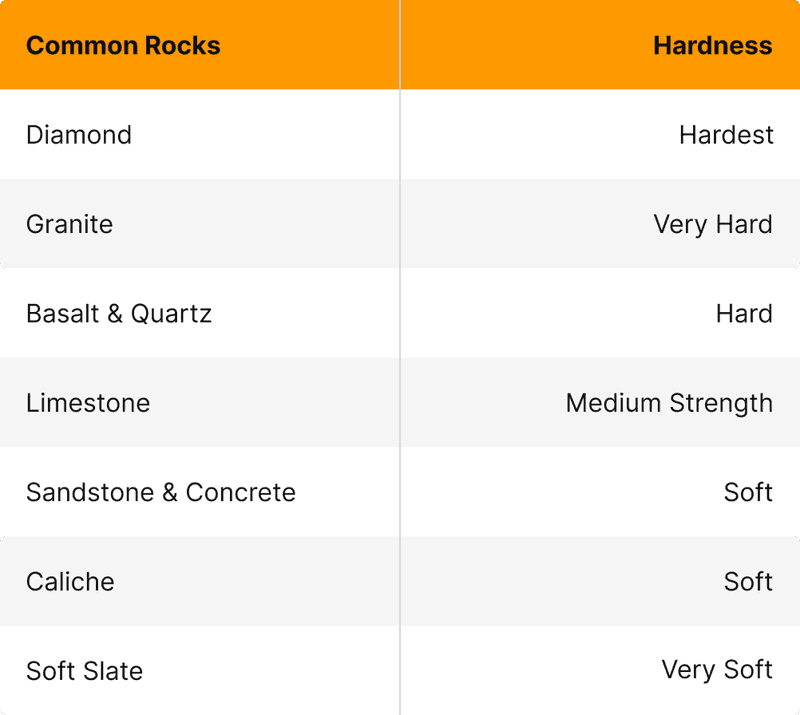

Stones come in a range of ‘hardnesses’ meaning some stones are harder than others. Hard rocks like granite have a stronger structure and are harder to break up - just think of how strong diamond is! Hard rock is great for building materials as it is very durable but in crushing this means that they will need a lot more energy and power to break them down. Soft stone like sandstone and limestone is crushed a lot more easily.

Stones vary in hardness, which affects how they should be crushed:

- Soft Rocks: Such as limestone and sandstone, are easier to crush and can often be processed with smaller, less powerful equipment.

- Hard Rocks: Like granite and basalt, require more force and are best handled with heavy-duty machinery.

A general rule: if the rock is harder than concrete or can't be scratched with a fingernail, it's considered hard and will need more robust crushing equipment.

Understanding Mohs hardness helps you select the right crusher for your material. For instance, softer aggregates may be processed efficiently using a small mobile crusher, while dense igneous rocks need robust primary jaw crushers followed by secondary cone crushers. Choosing the correct setup minimizes wear on your machines and maximizes productivity.

Proper selection of crushing equipment based on stone type also ensures the desired particle size and shape for your end product—whether you’re producing gravel for road construction or decorative stone for landscaping projects.

Equipment for Crushing Stone

Selecting the right equipment is crucial:

- Jaw Crushers: Ideal for primary crushing of hard materials. They use compressive force to break down large rocks.

- Impact Crushers: Suitable for secondary crushing and producing well-shaped, cubical aggregates. They use high-speed impact to fracture materials.

- Hydraulic Breakers: Useful for breaking up soft rocks or concrete before feeding them into crushers.

For example, the Omega J1065T is a heavy-duty jaw crusher suitable for hard rock, while the Terex Bison 120 is perfect for softer materials.

Each type of crusher plays a specific role in the crushing stages: primary, secondary, and tertiary. Primary jaw crushers handle the first break, while cone crushers and impactors refine the material for precise particle size distribution. Adding vibrating screens and conveyors ensures continuous, efficient throughput across the entire crushing plant.

When planning your operation, consider factors like feed size, production goals, and material abrasiveness. Heavier-duty crushers are better for high-volume quarry work, while compact mobile crushers are ideal for on-site recycling or smaller construction projects.

Do I need a screener to process crushed stone?

After crushing, it's essential to separate the material into different sizes using a screener. This process ensures that each size category—large stones, medium stones, small stones, and stone dust—is sorted for specific applications. For instance, the Barford 750J Jaw Crusher paired with a Barford 3-Way Screener can efficiently crush and sort materials on-site. At that point, the stones you have made can be used on your projects or sold to the public.

Screening is the final step in the stone crushing process and is vital for producing high-quality aggregate. Using vibrating screens allows you to separate materials into different fractions for specific end uses, such as road base, drainage stone, or decorative aggregate. Proper screening also ensures your crushed stone meets DOT or ASTM gradation standards.

Integrating a screener with your crusher—either as a standalone unit or part of a mobile closed-circuit setup—can significantly increase your plant’s efficiency and reduce handling time between crushing stages.

What can crushed stone be used for?

Crushed stone has many uses and is an excellent way to recycle excess rock waste that would otherwise be headed for the landfill. There is a high demand for crushed stone across many industries making it very popular with contractors.

Crushed stone is versatile and widely used in various industries:

- Construction: As a base material for roads, driveways, and foundations.

- Landscaping: For decorative purposes, pathways, and garden beds.

- Agriculture: Improving soil drainage and as a component in fertilizers.

- Erosion Control: Preventing soil erosion along waterways and embankments.

Here are a few ways crushed stone can be used in the construction and landscaping industries.

- To smooth and level roads under the pavement

- Enhance soil to improve crop growing conditions

- Stone fill to support pipes and drainage beds

- Protect roofing and reduce the heat from the sun

- Prevent ice and water erosion when building bridges

- As a buffer layer between concrete and soil

- Decorative purposes in landscaping

Since crushed stone can be left as chunky rocks or crushed as fine as sand, it is multipurpose and in high demand across nearly all areas of construction.

Crushed stone aggregate plays a critical role in the construction industry, from road construction to drainage and foundation stability. Its durability and high load-bearing capacity make it an essential raw material in infrastructure projects. Fine aggregates produced from impact crushers are often used for asphalt or concrete mixes, while coarser material serves as base rock or structural fill.

Because stone crushing transforms what was once waste into sellable product, it directly supports sustainability efforts and reduces reliance on natural quarry mining. Contractors producing their own aggregate on-site can generate new revenue while minimizing transportation emissions and landfill impact.

What equipment should I use to crush rock?

Different machines are used for different hardnesses of stone. The smaller jaw crushers will not be able to cope with large amounts of hard stone as they will cause a lot of wear-and-tear on the jaw plates. This would mean they would need regular maintenance and replacement. If you want to crush lots of hard rock you would need a heavy-duty machine such as the Omega J1065T jaw crusher or Rockster R900 impact crusher.

Most jaw crushers will crush soft rock quickly and easily. The ARK 704 jaw crusher would be a perfect machine for the job. Find a full list of the best stone and rock crushers here. Lets not forget about stone and rock screeners too - they are really important for making your DOT approved crushed stone product!

Choosing the right crushing equipment depends on your production goals, stone hardness, and desired end product. Jaw crushers are excellent for primary crushing of hard, abrasive materials like basalt and granite. Cone crushers are ideal for secondary or tertiary crushing where uniform particle size is needed, and impact crushers excel at shaping material for high-quality, cubical aggregate.

Mobile crushers and portable crushing plants offer flexibility for contractors working across multiple job sites. These compact machines integrate hoppers, conveyors, and vibrating screens, making it possible to crush, screen, and stockpile materials efficiently without a permanent plant. For high productivity in demanding conditions, heavy-duty rock crushers with reinforced components and wear-resistant liners are essential.

When setting up your stone crusher plant, consider adding a dust suppression system and magnetic separators to remove contaminants and protect your equipment. These additions not only improve performance but also enhance safety and environmental compliance.

Machinery Partner’s experts are here to help

With so many heavy equipment options out there, deciding which machine is best for your job can be difficult. Our experts can help you make that choice. They will talk you through the stone you want to crush vs. the heavy equipment suitable to get the job done. We are always here to help you figure out which machine is right for you, your budget, and your business. Contact one of Machinery Partner’s crushing experts today for more information. Check out our range of stone crushing machines here, including impact crushers for sale!

Machinery Partner specializes in crushers, screeners, concrete batch plants, & more. We are also here to help with financing and maintenance of all our machines to keep you up and running!

Our team can guide you through the full setup—from primary jaw crushers and secondary cone crushers to vibrating screeners and conveyors. Whether you’re building a stationary crushing plant or looking for a compact mobile crusher for on-site recycling, Machinery Partner has the solutions to keep your operation efficient and profitable.

We also provide support for long-term maintenance and replacement parts to minimize downtime and extend the lifespan of your crushing equipment. Partnering with us ensures access to the latest technology in sustainable, high-productivity stone crushing systems.

FAQs: Crushing Stone on Site

What is the easiest type of stone to crush?

Materials like limestone, shale, and sandstone are easier to crush. These are ideal for smaller crushers or entry-level setups and often don’t require as much power or wear part replacement.

What kind of crusher should I use for hard rock?

For tough materials like granite or basalt, start with a jaw crusher for primary crushing. If you need a cleaner or more uniform product, follow with an impact crusher for shaping.

Can I crush stone that has metal in it?

Yes. Many jaw crushers can handle reinforced concrete or mixed demolition material. A magnet can be added to remove metal like rebar or wire from the crushed output.

Do I need a screener after the crusher?

If you want sorted material by size, a screener is essential. It lets you separate fines from larger rock and create multiple products from a single load.

How much space do I need to crush stone on site?

Compact crusher and screener setups can run in tight spaces like driveways, small yards, or urban sites. You’ll need room for the machine, material piles, and safe access, but not much more.

Can I make money crushing stone?

Yes. Crushed stone sells well as base material, drainage rock, or clean fill. On-site crushing also cuts down on dumping fees, trucking, and buying aggregate, which improves margins quickly.

By setting up a mobile crushing operation, contractors can produce aggregate directly where it’s needed. With the right mix of crushers, screeners, and conveyors, it’s possible to create multiple high-quality stone products—from fine sand to coarse base—on the same job site.

Ready to start?

In short, stone crushing is one of the most cost-effective ways to manage raw materials while creating new revenue opportunities. From heavy-duty jaw crushers for primary reduction to precision screeners that deliver clean aggregate, Machinery Partner can help you build a complete crushing system that fits your business goals.

Explore our full range of stone crushers, screeners, and mobile crushing plants, and talk to our team about setting up your own high-efficiency stone crusher plant today.