Types of Crushers: Cone, Jaw, Impact, Gyratory and more

Article updated October 16, 2025

Choosing the right crusher is key to running an efficient material processing operation. Whether you're crushing rock, concrete, asphalt, or recycled material, understanding the different types of crushers and the stages of crushing can help you select the right equipment for your job ... and save time and money in the process.

Crushers form the heart of any modern crushing plant or processing plant, converting raw feed material into high-quality aggregate for construction, mining, and recycling applications. From primary crushing to tertiary and even quaternary reduction, each crusher type performs a unique role in the overall crushing operation.

What is a crusher?

Before we discover all the different types of crushers, we need to know what a crusher is and what it is used for. A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust.

This size reduction process allows contractors to turn raw material into usable aggregate, which is critical for road construction, asphalt production, and concrete mixing. Crushers achieve this by applying mechanical force—through compression, impact, or attrition—within a designated crushing chamber.

Every crusher operates inside a defined crushing cavity, with wear parts such as the bowl liner, mantle, and toggle plate engineered from manganese steel to withstand abrasive materials.

What is a crusher used for?

Crushers are mainly used in the mining and construction industries, where they are used to break down very large rocks and boulders into smaller pieces. Crushers are also commonly used for jobs like breaking up asphalt for roadwork or demolition projects.

In aggregate production and mineral processing, crushers prepare feed material for subsequent screening, conveying, or washing stages. Each crushing stage—primary, secondary, and tertiary—produces progressively smaller particle sizes and more refined gradation.

Crusher machines come in a wide variety of sizes and capacities, from small jaw crushers that cost the same as a new truck to extra large cone crushers that cost millions of dollars. With all this choice, you'll want to make sure that the one you choose has the power and capabilities necessary for your specific project. In most cases, having a crusher at your disposal can save a significant amount of time and labor since you won't have to do as much manually crushing materials yourself. This makes them an invaluable asset for anyone who may need to crush materials quickly and efficiently.

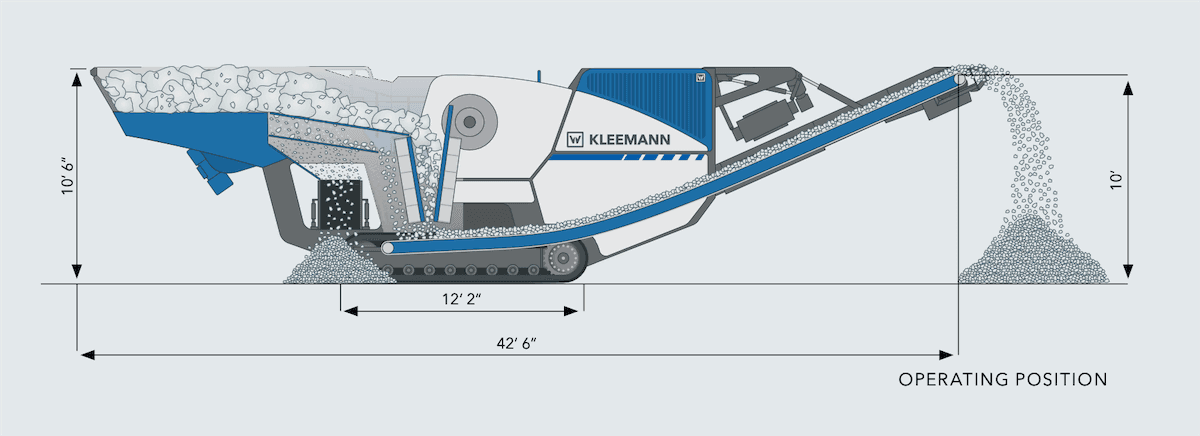

Mobile crushers and on-site setups now allow contractors to process material where it’s generated, eliminating trucking costs and giving real-time control over product size and reduction ratio.

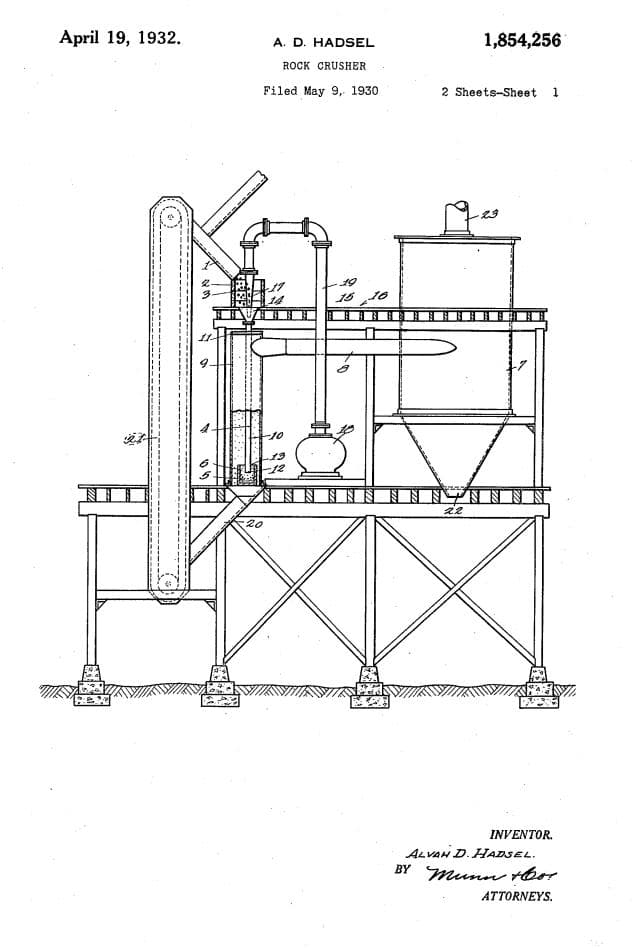

Brief history of crushers

The first United States patent for a rock crushing machine was in 1830. Its key technology was the drop hammer concept, found in the well-known stamp mill, which would be repeatedly linked to the golden age of mining. Ten years later, another U.S. patent was issued to an impact crusher. The primitive impact crusher was made up of a wooden box and a cylindrical wooden drum, with iron hammers fastened to it. While both of these patents were granted, neither creator ever marketed their inventions.

These early prototypes paved the way for mechanical crushing, influencing the compression and impact principles that power today’s crushers—from jaw crushers to VSI impactors.

Eli Whitney Blake invented, patented, and sold the first actual rock crusher in 1858; it was known as the Blake Jaw Crusher. Blake’s crusher was so influential that today’s models are still compared to his original designs. This is because the Blake Jaw Crusher integrated a key mechanical principle—the toggle linkage—a concept students of mechanics are familiar with.

Modern single-toggle and double-toggle jaw crushers still rely on this same mechanism, where the fixed jaw and moving jaw create powerful compressive forces to handle even the hardest materials.

In 1881, Philetus W. Gates received a U.S. patent for his device featuring the basic ideas of today’s gyratory crushers. In 1883, Mr. Blake challenged Mr. Gates to crush 9 cubic yards of stone in a contest to see which crusher would finish the job faster. The Gates crusher completed the task 40 minutes sooner!

The gyratory crusher introduced continuous crushing via a rotating eccentric shaft and concave bowl liner—key elements of high-capacity primary crushers still used in quarries today.

The Gates’ gyratory crushers were preferred by the mining industry for almost two decades until the turn of the century, circa 1910, when Blake’s jaw crushers saw a resurgence in popularity. The demand for large jaw crushers skyrocketed as the industry began to understand their potential as primary crushers in rock quarries. Through Thomas A. Edison’s research and development, giant machines were innovated and placed around the United States. Smaller-sized jaw crushers were also developed as secondary and tertiary crushers.

Edison’s studies within the field of mining and crushing left a legacy that forever improved how large rocks and materials are reduced.

This progression established the full crushing stage hierarchy—primary, secondary, tertiary, and quaternary—each stage tailored for feed size, throughput, and desired finished product.

Basic ways to reduce material size

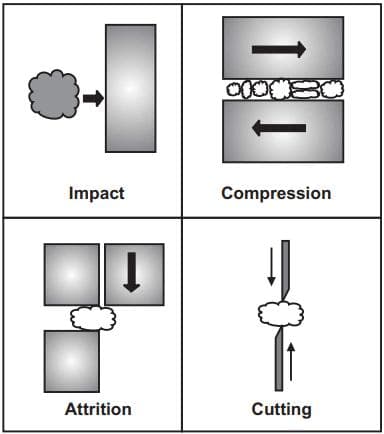

Crushing is the process of reducing or breaking down larger-sized material into smaller-sized material. There are four basic ways to crush: impact, attrition, shear (cutting), and compression.

Each method corresponds to a different crusher design and determines how efficiently the equipment handles specific types of materials—from soft gypsum to hard basalt.

Impact: Instant collisions of large objects against one another with material placed between. Both objects can be in motion, or one can be still while the other strikes against it. There are two main types of impact reduction: gravity and dynamic.

Impact crushers, hammer mills, and HSI/VSI impactors use this principle to produce fine, cubical products for asphalt and concrete. High-speed impact creates uniform particle size and excellent gradation for finished aggregate.

Attrition: Rubbing the material between two solid surfaces. This is an appropriate method when reducing less abrasive materials because it consumes less power during the process. Robust materials would not be as efficient.

Used in certain tertiary and quaternary crushers where minimal fines and smooth particle shape are desired, attrition minimizes wear on components while providing controlled size reduction.

Shear: Typically combined with other reduction methods, shearing uses a trimming method and is used when a coarse outcome is wanted. This reduction method is often seen in primary crushing.

Roll crushers employ shear and compression together, ideal for medium-hard materials or when a precise top size is required.

Compression: A key mechanical element of jaw crushers, compression reduces materials between two surfaces. Great for very hard, abrasive materials that do not fit attrition crushers. Compression is unsuitable for anything tacky or gummy.

This principle defines compression crushers like jaw, cone, and gyratory models, which excel at handling hard, abrasive materials with minimal fines generation.

Selecting the proper crushing action—impact, compression, or shear—directly affects reduction ratio, wear part longevity, and the overall efficiency of your crushing operation.

Understanding Crushing Stages

Crushing operations are typically divided into stages, each serving a specific purpose:

- Primary Crushing: The first stage that reduces large materials into manageable sizes.

- Secondary Crushing: Further reduces material size for specific applications.

- Tertiary and Quaternary Crushing: Achieves fine material sizes for precise specifications.

Modern crushing plants integrate multiple crushers with conveyors, vibrating screeners, and control systems to ensure continuous throughput, precise gradation, and optimized energy use across every crushing stage.

What are the different kinds of crushers?

There are lots of different kinds of crushers, from jaw crushers to impactors and cone crushers. Crushing is a versatile process, and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary, all of which have their own unique benefits. Let's find out why each of these crushing stages is important.

Primary crushing equipment

Run-of-mine (ROM) materials are brought directly from blasting projects and crushed in a primary crusher for the first reduction. Primary crushing produces materials ranging from 50” to 20” on average. The two main types of primary crushers are jaw crushers and gyratory crushers.

These heavy-duty machines handle the hardest rocks—basalt, granite, and reinforced concrete—forming the foundation of any efficient crushing process.

Jaw crushers

Large amounts of material are fed into the “V-shaped” jaw of this crusher and are reduced using compressive force. One side of the V remains stationary (the fixed jaw) while the other side swings via an eccentric shaft.

The crushing chamber narrows toward the bottom, creating a powerful compressive action that delivers a consistent reduction ratio and predictable product size. Single-toggle jaw crushers are prized for simplicity, while double-toggle designs provide extra force for hard rocks and abrasive materials. To find out more about primary jaw crusher check out our blog.

Advantages: Simple maintenance, long-lasting manganese wear parts, and high throughput.

Applications: Quarries, demolition recycling, and portable on-site crushing setups.

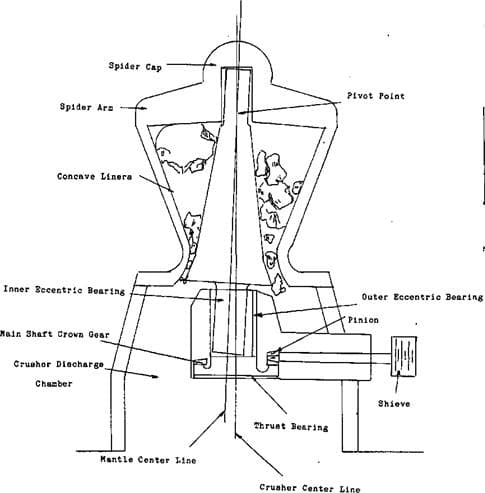

Gyratory crushers

Material enters the upper hopper where the mantle and concave bowl liner create a continuous compression motion. The gyrating spindle crushes rock against the chamber walls, producing a steady flow of crushed material.

These crushers achieve higher capacity and smoother operation than jaw crushers, making them preferred for large mining and aggregate plants requiring high-volume primary reduction.

Advantages: Constant feed capability, uniform particle size, and low operating costs per ton.

Applications: Primary crushing stage for hard rock, metallic ore, and large-scale aggregate production.

Secondary crushing equipment

After the first stage, secondary crushers take material from 13” down to 4” or smaller.

This stage focuses on refining particle shape and controlling gradation to produce specification-ready aggregate. Common equipment includes cone crushers, impact crushers, and roll crushers.

Cone crushers

Cone crushers use a rotating mantle inside a stationary concave to compress feed material. The material breaks as it moves downward through the crushing chamber, producing a fine, well-graded output.

These compression crushers excel with medium-hard to hard materials and provide excellent shape control, making them essential in both secondary and tertiary crushing stages.

Key Components: Mantle, bowl liner, feed opening, and adjustable closed-side setting (CSS) that determines final product size.

Applications: Asphalt production, road base, and concrete aggregates.

Impact Crushers

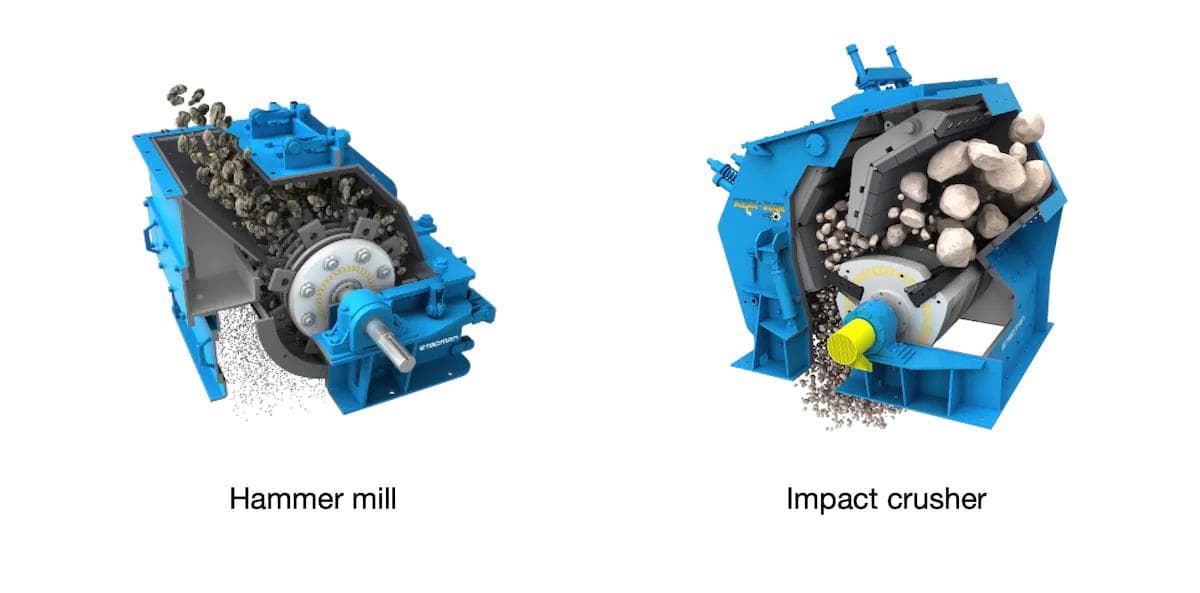

Impact crushers (including HSI and VSI models) use high-speed rotors to hurl material against impact plates.

Horizontal shaft impactors (HSI) deliver strong reduction ratios and produce a cubical product ideal for concrete and asphalt, while vertical shaft impactors (VSI) are used for shaping and fine aggregate production.

Advantages: Excellent gradation control, ability to handle both soft and hard rock, and high production efficiency.

Applications: Recycling, tertiary crushing, and sand manufacturing.

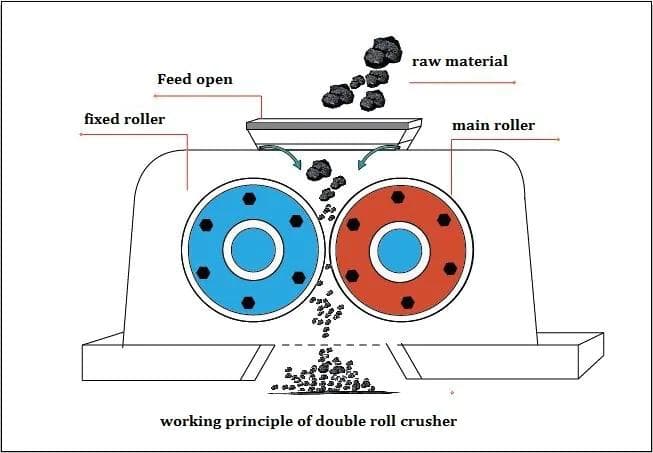

Roll crushers

A roll (or roller) crusher reduces material by compressing it between two turning cylinders, parallel to each other. The cylinders are mounted horizontally, with one resting on strong springs and the other framed permanently. Material is then fed between the two. Changing the distance between the rollers allows you to control the desired material output size. Each cylinder is easily adjusted and lined with manganese for maximum long-term wear. Roller crushers typically deliver fine material output and are not suitable for hard or abrasive materials.

They offer a precise top size control and low dust production, ideal for fine crushing in limestone, gypsum, and soft mineral applications.

Advantages: Simple design, minimal fines, and reliable performance with medium-hard materials.

Applications: Secondary and tertiary stages in mineral processing or on-site aggregate production.

Hammer mills and impact crushers

One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers. Hammer mill crushers use continuous hammer blows to shatter and disintegrate material. They are typically horizontally rotating in an enclosed cylinder casing. The hammers are attached to a disk and swing with centrifugal force against the casing. Material is fed into the top and crushed as it falls through the hole at the bottom. You will find hammer mills being used in industries like agriculture, medicine, energy, and beyond. They provide some of the highest efficiency outputs available, are portable, and can handle almost any material.

Impact crushers have a very similar working principle except instead of the rotating parts hitting the material like a hammer, they instead throw the material against an impact plate, which breaks it down. They also come in horizontal or vertical shaft configurations depending on the desired output. For more information on impact crushers check out this blog. Check out impact crushers for sale at Machinery Partner.

Tertiary crushing equipment and beyond

Sometimes you might need to continue to reduce the size of your crushed material, and a tertiary reduction may be desired (sometimes even further). Particle sizes range from 5" to 1" during this final stage. Tertiary crushing is highly valuable in the mineral processing industry. The degree to which a material is reduced largely depends on how fine the material’s final size should be. More stages of crushing = smaller-sized products. For tertiary crushing, you will most likely need a smaller impactor or cone crusher.

Screening and multiple crushing sequences can also limit material waste. Some common tools used during the process are:

Screening Equipment: If a piece of material is too large for the crushing machine to effectively handle, it must be removed. Screening equipment removes any material that will slow the production process. It sorts and classifies materials by size using a series of screens with different-sized openings. These openings, or grids, allow small rocks to move along and large rocks to be excluded. If the material does not fit through the openings, it will be excluded from the next phase of the reduction process. Then, it is either sent back into the crushing process for further size reduction or removed completely from production. Screening equipment is crucial to an effective tertiary crushing operation, as large materials can take up needed space and consume valuable energy, creating delays and costing money.

Conveyors: Moving raw materials and reduced materials from one stage of production to the next can be incredibly time-consuming. Modern mining and material handling methods now include extensive conveyor systems that can sometimes cover many miles. There are two basic kinds of conveyors: powered and gravity. Powered conveyors utilize energy from an outside source, whereas gravity conveyors use the material’s weight to propel them.

Crusher Selection and Maintenance

Choosing the right crusher depends on:

- Feed size and hardness of raw material

- Desired product size and shape

- Reduction ratio and crushing stage

- Operating costs and wear part longevity

Preventive maintenance—replacing wear parts like mantles, toggle plates, and liners—ensures efficiency and minimizes downtime. Modern crushers also use automation to monitor chamber pressure and feed level for optimal performance.

What is the difference between a cone crusher and gyratory crusher?

Gyratory crushers and cone crushers are both types of compression crushers that crush materials by squeezing them between a stationary and a moving piece of manganese-hardened steel. There are however some key differences between cone and gyratory crushers.

Firstly, gyratory crushers are designed for crushing very large materials—normally in the primary crushing stage—while cone crushers are typically used for secondary or tertiary crushing to make smaller, finer products. Secondly, the shape of the crushing head is different. The gyratory crusher has a conical-shaped head that gyrates inside a bowl-shaped outer shell, while the cone crusher has a mantle and a stationary concave ring.

Additionally, gyratory crushers have a higher crushing ratio (meaning that they can crush large material into smaller pieces), a larger feed opening, and a more consistent product size and shape compared to cone crushers. However, cone crushers have a more efficient crushing action for smaller materials but can produce more fines. For more information on crusher reduction ratios, check out our blog.

Do different types of crushers make different shaped products?

Yes, different types of crushers produce different shaped products, and this matters depending on what you're using the material for.

Jaw crushers are designed for primary crushing and use a compressive force to break material. They produce more angular, flat, or elongated pieces, which are fine for road base, backfill, or sub-grade layers where shape doesn’t need to be precise.

Impact crushers, on the other hand, use high-speed impact force to break material and tend to produce more uniform, cubical-shaped products. This makes them a better choice when you're creating finished material for concrete mixes, asphalt, or resale, where clean edges and consistency matter.

Choosing between these two often comes down to the final product spec and whether you need shape or just size reduction.

Let Us be Your Machinery Partner

Not sure which crusher fits your job? Talk to our team and get matched with the right machine for your material, volume, and budget.

Watch your business grow with the right equipment for the right job—supplied by Machinery Partner. If you want to get expert advice on the right crusher for your business, get in contact with one of our experts today.

You can also check out our full range of crushing equipment, screening equipment and heavy equipment brands like ARK & more sourced directly from the manufacturer.

FAQs: Types of Crushers and Crushing Stages

What are the main stages of crushing?

Most material processing involves three key stages:

- Primary crushing breaks down large material (like concrete or rock) into smaller, manageable chunks.

- Secondary crushing refines those chunks into usable sizes.

- Tertiary crushing creates fine, consistent material when a very specific gradation is needed.

Why are different crushers used at each stage?

Each type of crusher is designed for a specific job. Jaw crushers are tough and ideal for primary crushing. Impact crushers or cone crushers are better for secondary and tertiary stages where shaping and final sizing matter.

What’s the difference between a jaw crusher and an impact crusher?

Jaw crushers use compression and produce rough, angular output. They’re best for breaking down large, hard material. Impact crushers use high-speed impact to produce a more uniform, cubical product, making them better for finished material or resale.

Can I skip secondary or tertiary crushing?

Yes, depending on your project. If you only need to break material down for backfill or on-site use, a jaw crusher alone might be enough. But if you need clean, spec material for resale or paving, secondary or tertiary crushing is often required.

Do I need a screener with my crushing setup?

If you're trying to sort material into different sizes or remove fines, a screener is essential. It ensures you get the right product for the right application — and helps you hit specs if you're reselling aggregate.

Which crusher should I start with?

Start by considering your material type, required output size, and production goals. Most setups begin with a jaw crusher for primary reduction. From there, you can add an impact crusher or cone depending on the final product you need.