Top 3 crushing set-ups for concrete recycling

Article updated October 08, 2025

Did you know that your waste concrete could be turned into a valuable construction material?

Imagine turning what would otherwise have been thrown away or dumped into a useful aggregate that can help your business make money and save the planet at the same time. Want to know more? In this article, we will show you the different types of crushers and help you choose one that fits your business best.

These machines, ranging from compact mobile crushers to full-scale tracked impactors, are designed for efficient on-site concrete recycling. By crushing concrete slabs, rebar, and demolition debris directly at the job site, contractors can eliminate landfill disposal costs and create reusable aggregate for backfill or road base.

Most common crushers: jaw vs impact

The two most common types of concrete crushers are jaw crushers and impact crushers. Each has its own advantages depending on your material type, desired end product, and project scale. Understanding how each works helps you choose the right setup for your operation.

Jaw crusher

The name jaw comes from the mechanical action of the crusher breaking up rock and concrete in the same way our jaws break up food. One fixed and one swinging plate allows the crusher to easily break up concrete slabs and other hard, abrasive materials. Crushed output will be more slate-like with an oblong shape because it relies on the material fracturing along its own natural grain lines.

Jaw crushers are heavy-duty crushing machines ideal for primary reduction of concrete, stone, and asphalt. They’re designed to handle reinforced concrete with embedded rebar, making them perfect for demolition and recycling projects. The high compression force and simple mechanics also mean fewer moving parts and lower downtime.

When paired with a screener or conveyor system, a jaw crusher can produce uniform aggregate for reuse in driveways, road base, or drainage applications. Compact tracked jaw crushers are especially popular among contractors working with limited space or moving between multiple job sites.

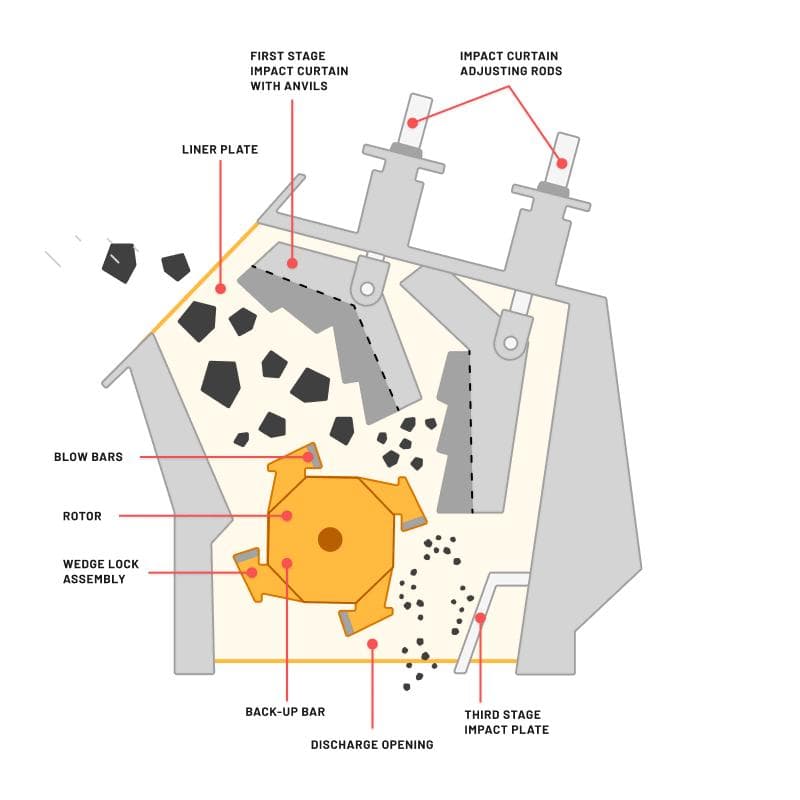

Impact crusher

Impact crushers break concrete with a rotor. The rotor contains "hammers,” which hit the feed material and throw it against impact plates inside the crusher. Unlike jaw crushers, which have a fixed gap through which the material can pass, impact crushers have a variable output size. This means that the end product will be a mixture of different sizes. Oversized pieces of concrete will be removed by a recirculation screen and returned back into the crusher to be broken down further, removing the need for a secondary crusher.

Impact crushers excel at producing cubical, high-quality end products ideal for use in concrete mixes, compacted bases, and asphalt blends. Their adjustable settings and closed circuit design enable operators to fine-tune particle size, making them one of the most versatile machines in modern concrete recycling.

Since the output is cuboid/spherical in shape, it makes the material produced by impact crushers better for compacting and transporting. These qualities make impact crusher products more desirable than jaw crusher output.

Impact crushers are also favored for their high throughput and reduced need for secondary screening. With proper configuration, a single impactor can handle 100–300 TPH (tons per hour) depending on material hardness and feed size.

Is there a difference in the shape and size of product produced from a Jaw Crusher vs Impact Crusher?

Jaw crushers typically produce more elongated, slab-like particles because they break material along its natural grain. This results in crushed concrete or stone that can be irregular in shape, which may affect how well it compacts or fits together. In contrast, impact crushers use high-speed hammers to shatter material, resulting in more cubical, rounded particles. This cubical shape is often preferred for road base, concrete mixes, and applications where tight compaction is needed. Choosing the right crusher for your project means considering not just output size, but also the shape of the material you need for your end use. Just check out the photo below to see the difference!

For on-site concrete recycling, impact crushers generally yield superior compaction and smoother material flow. However, jaw crushers are more durable for heavy-duty applications involving large chunks of reinforced concrete or mixed demolition waste. Many operators choose to pair both machines in sequence for maximum efficiency — using a jaw crusher for primary breaking and an impactor for finishing.

What is the best concrete crusher for your business?

The choice of the crusher depends on multiple factors, such as the size of your business, your budget, and the type of material you want—for example, if you want to produce DOT approved material*. It also depends on your crushing expertise and ability to service and maintain your machines.

Before deciding, evaluate your average project size, transportation requirements, and material type. Crushing reinforced concrete with rebar requires more robust machinery, while lighter demolition waste can be handled efficiently with compact crushers or skid steer attachments.

A small jaw crusher: The beginner

Your experience level:

- I'm starting my crushing business.

- Normally I send waste to landfills, but I'd like to reduce the amount.

- I want to add another service to my business.

- I’m interested to find out how much revenue crushing could generate.

Your needs:

- I want to make my own material.

- The material will be reused for residential or private projects—no requirement for DOT approval.

- I need 3/4” crushed concrete or crushed stones of no particular size.

- It must be easy to use.

Budget: From $85k

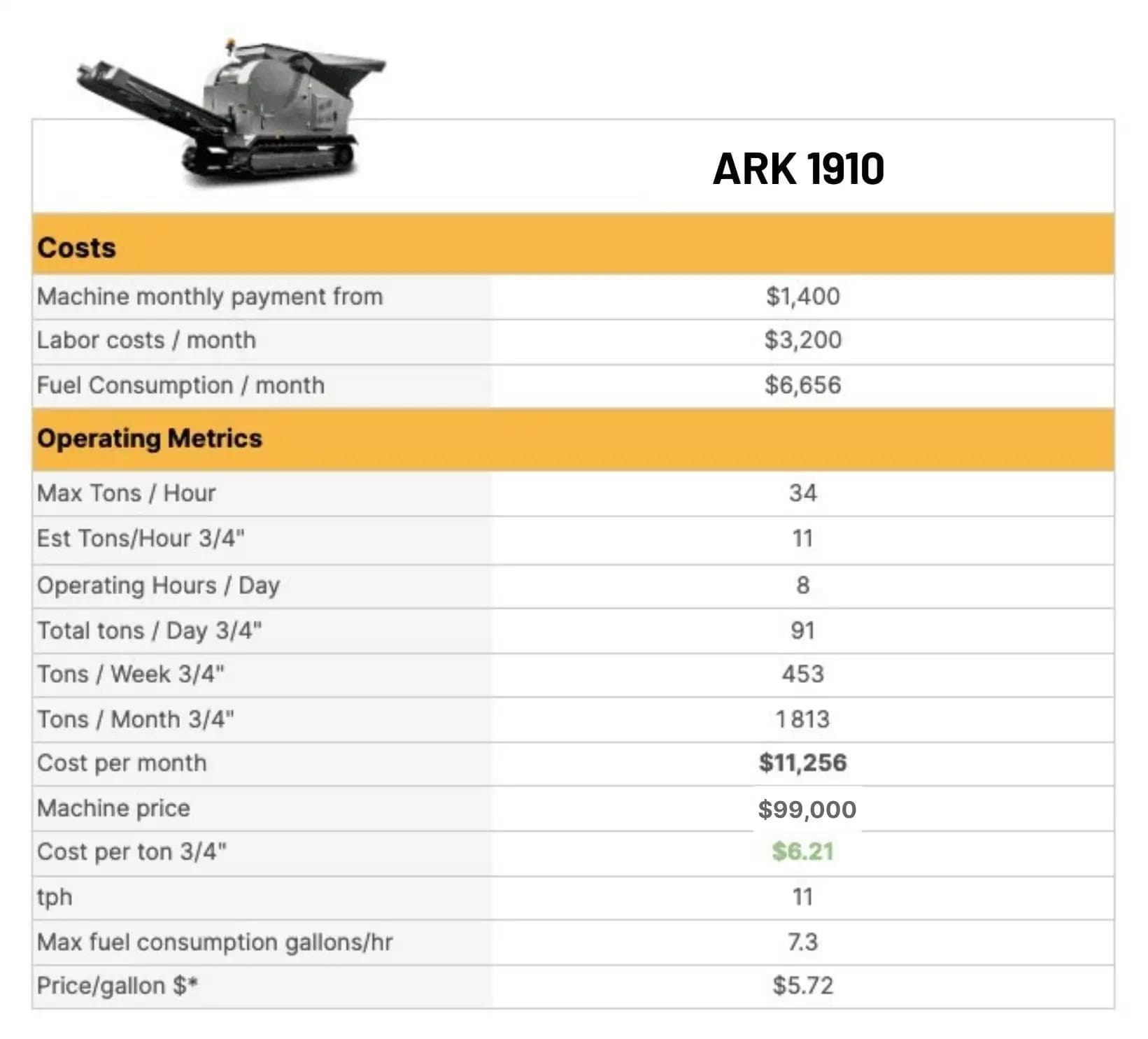

Recommended machine: A small tracked jaw crusher

Small, tracked jaw crushers are designed for contractors who want to process concrete slabs, asphalt, or rock directly on the job site. They typically produce 10–50 TPH and can fit on trailers for easy transport between projects. Because these machines are compact, they’re ideal for urban work or smaller demolition projects.

What are the benefits for your business?

- Ideal machine for recycling construction and demolition waste.

- Suitable for concrete, rock, cement, and more.

- This jaw crusher is compact and equipped with tracks for better mobility.

- Last but not least, you can reduce transport costs by reusing crushed material directly on your demolition site. Smaller material is more easily compacted and takes up less space, reducing the number of dumpsters needed.

With minimal setup and low fuel consumption (often under 3 gallons per hour), compact crushers provide an affordable entry point for small contractors looking to eliminate disposal costs and generate aggregate on-site.

Specifications:

What else should I consider as a contractor getting into crushing for the first time?

Robust Construction for Extended Service Life

High-quality concrete crushers are built with heavy-duty materials designed to resist wear and tear. Features such as abrasion-resistant steel components, thick hopper wear plates, and reinforced frames ensure that your equipment can handle high-impact loads and abrasive materials without premature failure. For example, some leading crushers use Tri-Braze steel for wear items and incorporate replaceable carbide bits to further extend service life.

Get a Crusher Designed for Easy Maintenance

Ease of maintenance is another hallmark of a well-designed crusher. Look for features such as quick-access panels, modular wear parts, and tool-free component swaps. These details make routine inspections and part replacements faster and safer, helping you keep service intervals short and maintenance costs low.

Many modern compact crushers also include built-in telematics or remote monitoring systems to track fuel usage, output, and downtime—giving you valuable data for optimizing productivity.

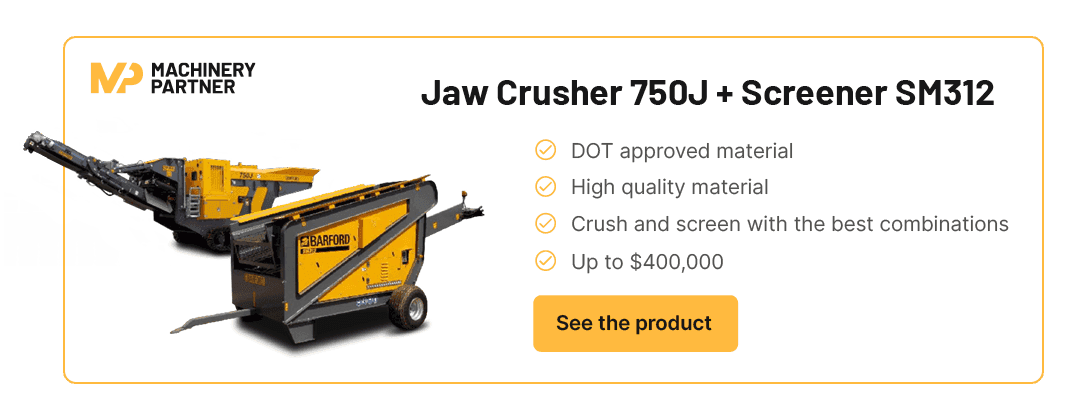

A mid-sized jaw crusher & screener: The intermediate

Your experience level:

- I have already started crushing

- I know there is an opportunity to make my own construction material by recycling.

Your needs:

- My budget is limited, but I need a machine with the same capabilities as the impact crusher.

- I want to produce DOT-approved materials that I can sell.

Budget: $300k to $700k

Recommended Machine: A mid-sized jaw crusher and screener combined

This setup is ideal for contractors handling larger demolition or roadwork jobs. A mid-sized jaw crusher paired with a two-deck screener provides flexibility to produce multiple material grades—typically 50–150 TPH depending on feed material and configuration.

What are the benefits for your business?

- With this combined machine, you can have your own on-site recycling plant.

- The crusher/screener combination provides excellent versatility: it can process asphalt, demolition waste, recycling waste, concrete, and much more.

- You can screen material into two different sizes of product.

- The machine can fit inside a container. So it can be moved from site to site with ease.

- The volume capacity of the jaw crusher + screener is approximately 50 tph to 150 tph, depending on configuration.

When paired with a loader and conveyor, this setup becomes a self-contained crushing operation. Contractors can process, screen, and reuse aggregate directly at the job site, reducing hauling, downtime, and dependence on external suppliers.

Specifications:

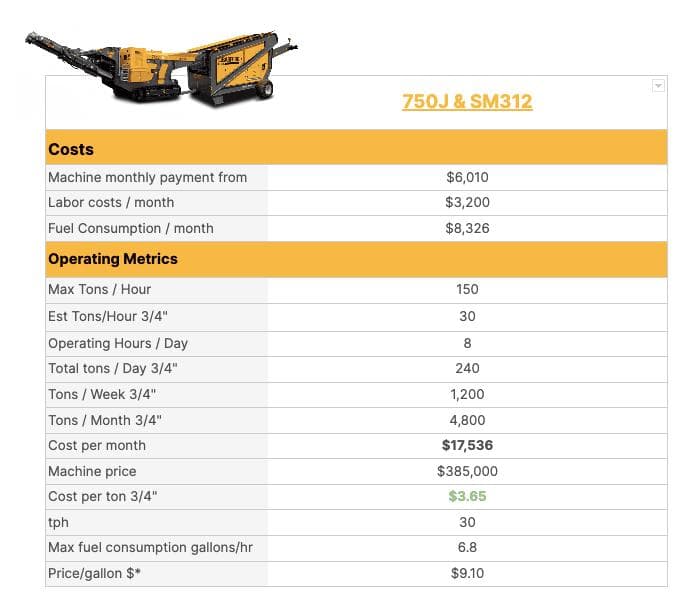

The impactor: the “all in one” for the expert

Your experience level:

- I have good knowledge about crushing.

- I am already selling or reusing crushed material.

Your needs:

- I want to make my own DOT-approved material.

- I need to crush and screen with one machine.

- Increasing the value of the material that I am selling right now.

- I want a higher output volume.

Recommended machine: An impact crusher

Impact crushers—often called mobile impactors—are the go-to choice for high-volume producers who need excellent control over particle shape and size. These machines can handle concrete, asphalt, stone, and rebar while maintaining continuous throughput of up to 300 TPH.

What are the benefits for your business?

- An all-in-one machine featuring a closed circuit crusher allows you to crush and screen simultaneously.

- This is one of the biggest and most powerful mobile impactors on the market. It can reduce the size of materials at a high input-to-output ratio.

- No need to worry about blocking issues: Thanks to its release system, the machine can solve them itself.

- It requires only one person to operate the whole system. The rest of your team can be dedicated to other business needs.

- Easy to set up, use, and maintain.

- Heavy-duty impactor capable of running all day.

Many impact crushers include built-in conveyors, magnets for rebar removal, and dust suppression systems for safe and efficient operation. These mobile crushing plants are ideal for contractors managing large infrastructure, roadwork, or commercial demolition projects.

Choosing to recycle your concrete is a great decision for both the environment and your pocket. Depending on your knowledge of mobile crushing, your needs (size of material to be crushed and type of product required), and your budget, selecting the best concrete crusher for your business can be a difficult process.

Why Every Contractor Needs a Concrete Crusher: Key Benefits and Cost Savings

Owning a concrete crusher can transform the way you handle waste material on your job sites, turning a costly problem into a profitable opportunity. Here’s why investing in a concrete crusher makes sense for contractors of all sizes:

1. Significant Cost Savings

Hauling and disposing of concrete waste at a landfill is expensive, with fees that add up quickly over multiple projects. By crushing your own concrete on-site, you eliminate these disposal costs entirely. Instead of paying to get rid of material, you can process it into valuable aggregate for reuse or sale, effectively turning waste into a revenue stream.

On-site crushing can reduce waste management costs by up to 80%, depending on your disposal rates and hauling distances. Over time, this makes owning a crusher one of the most cost-effective investments a contractor can make.

2. Reduce Material and Transportation Expenses

Purchasing new aggregate for backfill, driveways, or road bases can be a major expense. With a concrete crusher, you can produce your own high-quality recycled material right where you need it. This not only saves on the cost of buying new materials but also slashes transportation expenses and the time spent waiting for deliveries.

Producing recycled aggregate directly at your job site also reduces emissions from trucking and quarry operations, helping contractors meet sustainability and carbon-reduction targets.

3. Boost Project Efficiency and Flexibility

Having a crusher on-site means you’re in control of your material supply. There’s no need to coordinate with external suppliers or worry about delays due to material shortages. You can keep projects moving, adjust quantities as needed, and respond quickly to changing requirements.

Modern compact crushers can be set up in under 30 minutes and adjusted for different materials, giving your team unmatched flexibility between demolition and backfill phases.

4. Environmental Responsibility

Crushing and reusing concrete reduces landfill waste and the demand for new natural resources. This not only helps you meet sustainability goals but also appeals to clients who value environmentally friendly practices.

By reusing demolished concrete and asphalt, contractors actively participate in circular economy practices, reducing overall environmental impact while cutting waste-handling costs.

5. Competitive Advantage

Contractors who can offer in-house recycling and material production stand out in a crowded market. By delivering faster, more cost-effective, and greener solutions, you can win more bids and increase your profit margins.

Providing your clients with the option to recycle materials on-site demonstrates innovation and environmental leadership, positioning your business as a preferred contractor for public and private projects.

6. Versatility for Multiple Applications

Modern concrete crushers handle a variety of materials, including bricks, asphalt, and stone making them useful for a wide range of projects. Whether you’re working on demolition, roadwork, or new construction, a crusher adds value across your operations.

Many crushers now come equipped with quick couplers and hydraulic adjustments for use with excavators or skid steers. This flexibility allows one machine to handle concrete slabs, rock, and even light masonry without switching setups.

In summary:

A concrete crusher is more than just a piece of equipment—it’s a strategic investment that helps contractors save money, reduce waste, and gain greater control over their projects. By bringing material processing in-house, you’ll improve your bottom line and set your business up for long-term success.

Whether you’re a small demolition crew or a large construction firm, on-site crushing provides unmatched efficiency, sustainability, and profitability. Explore Machinery Partner’s range of mobile crushers today and start turning waste into opportunity.

Get Help Choosing Your Perfect Concrete Crusher

Still not sure which machine is right for you and your business? Machinery partner carries a full range of crushers to match every budget and use case, so reach out today to speak directly with one of our crushing experts.

We also supply a huge range of equipment from screeners to screeners and shredders for all your business needs!

Our specialists can help you compare different crusher models, from compact jaw crushers to high-output mobile impactors, and calculate your return on investment based on throughput, downtime, and operating costs.

*What is DOT-approved material?

To ensure the safe transportation of materials, the Department of Transportation (DOT) in the U.S. defines the standards for classification and labelling of construction materials. The Approved Materials List (AML) was developed to know the materials that need extensive sampling/testing, performance evaluation, source audits, etc. These requirements provide for packaging specifications and afford operational rules that must be followed. DOT-approved material is only required for certain/specific jobs such as large roadworks, infrastructure, and building projects. Most residential and smaller projects don’t need to follow these requirements.