How to make money recycling concrete

Article updated October 09, 2025

Concrete is the single most widely used material in the world after water. 4.4 billion tons of the substance are produced every year, and in the construction industry, it is used twice as much as all other building materials combined!

You're now asking yourself, 'how can I make money from concrete?' - To help you get started, we put together this post to cover the financial benefits of recycling concrete, how your company can do it, how much money you can make crushing concrete and what processes are involved.

Recycling concrete is part of a growing movement toward sustainable construction and a circular economy. Instead of sending old concrete to a landfill, contractors can repurpose it into usable aggregate, reducing both environmental impact and material costs.

How concrete is recycled

Recycling concrete is achieved by breaking it down using crushing equipment such as a jaw crusher. It can be processed and broken down further by using an impactor crusher to produce a finer aggregate.

It can also be screened to separate the finer material from the chunkier pieces; now the concrete aggregate is ready to be repurposed as road base, fill, or decorative stone.

If necessary, specialized equipment like water flotation systems, concrete wash plants, and magnets are used to remove any unwanted foreign matter that might be mixed in with the crushed concrete.

This process transforms demolished concrete into a valuable secondary raw material known as recycled concrete aggregate (RCA). The RCA can then be used in new concrete mixes, infrastructure, and landscaping projects—helping conserve natural resources and reduce greenhouse gas emissions from new material production.

Concrete recycling operations often involve several steps: primary crushing to reduce size, screening to sort particle grades, and secondary processing to remove contaminants such as rebar, dirt, or asphalt residue. Each step improves material quality and makes it suitable for a wider range of construction applications.

Uses for recycled concrete

Recycled concrete aggregates can replace traditional rock or gravel in most construction and roadwork applications. Crushed concrete is commonly used as base material beneath roads, sidewalks, parking lots, and embankments. It performs well in these roles and even provides added drainage benefits compared to standard poured concrete, reducing pooling and slip hazards.

In addition to heavy civil projects, recycled concrete is also used in residential and commercial construction as compactable fill material and subbase under new concrete or asphalt. When properly processed, RCA can meet ASTM and Department of Transportation (DOT) standards for use in load-bearing layers.

Recycled concrete is versatile and can replace virgin aggregates in many projects:

- Road Base: Provides a stable foundation for roads and highways.

- Backfill: Used in trenches and retaining walls.

- Landscaping: Ideal for pathways, patios, and decorative features.

- Drainage Systems: Allows water to filter through, reducing runoff.

Some innovative builders are even incorporating recycled concrete into new concrete production, blending it with cement paste to form sustainable mixes that meet modern structural performance requirements.

By reusing concrete, contractors not only save on material costs but also contribute to environmental sustainability.

Every ton of recycled concrete diverts roughly one ton of waste from landfill and offsets the need for newly mined aggregates. This reduces transportation costs, diesel emissions, and the depletion of limited natural stone resources—key benefits in achieving sustainable construction goals.

For contractors in paving, site work, or demolition, recycling concrete on-site offers a smart way to lower material and disposal costs. Instead of hauling broken slab to a landfill and paying for new aggregate, you can crush it down and reuse it directly on your job. This reduces fuel use, truck time, rental fees, and tipping charges — turning what would be waste into a profitable resource. It's a simple shift that improves margins and adds long-term value to your business.

From another perspective, it makes an ideal mulch, stone, or gravel replacement ready to be used in gardens, as long as it is effectively cleared of foreign matter. For more information on the pros & cons of recycled concrete, check out our blog!

Contractors who implement concrete recycling on their job sites often find that it becomes a long-term competitive advantage. Beyond saving money, it positions their businesses as environmentally responsible and compliant with modern sustainability standards.

How can I make money recycling concrete?

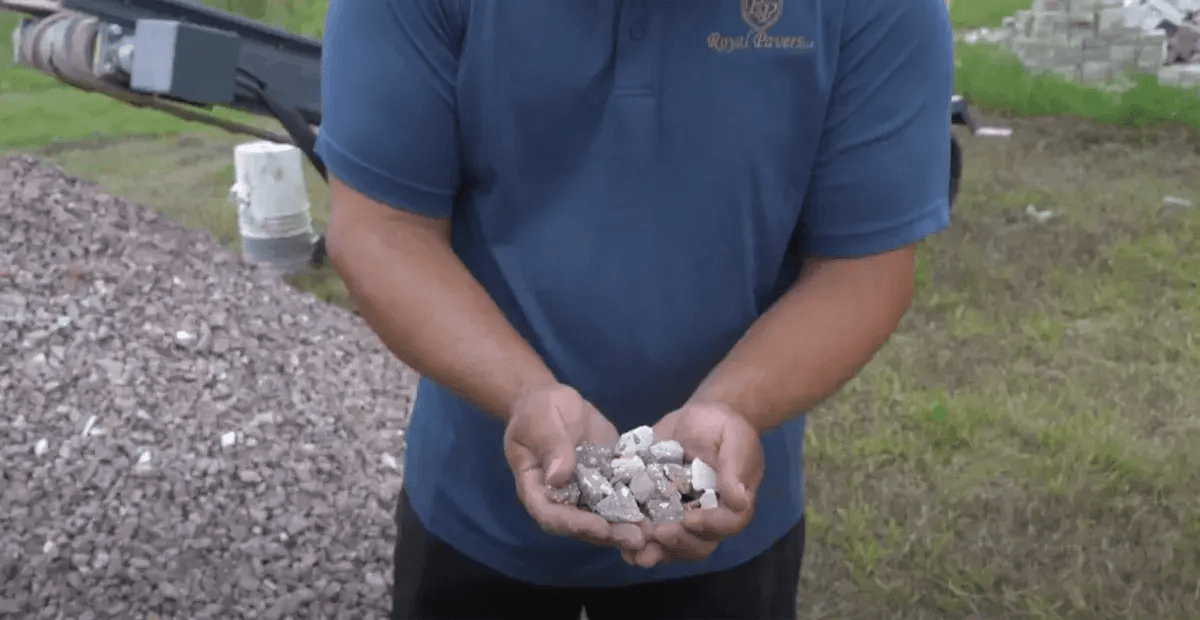

Don't just take our word for it - check out our customer Fabian who is saving over $1,000 a week crushing his own material. You can check out Fabian from Royal Pavers full customer case study here or watch below.

If we start with the cost of renting a 25-yard dumpster is approximately $500 USD without permits and taxes.

The other option is that you would transport the concrete yourself; in this situation, you can expect to pay at the landfill approximately $53 per ton without including the transportation costs.

We hear a lot of our customers tell us they are paying thousands of dollars a month just to get rid of waste concrete, which someone else is crushing and making money from.

For contractors who regularly demolish driveways, sidewalks, or parking lots, these disposal costs add up fast. By investing in compact crushing equipment, you can transform what was once a waste expense into a new revenue stream. Every ton you recycle saves on tipping fees and creates a marketable recycled material.

Cost breakdown of crushing your own concrete & owning a crusher

Compare this to renting or buying a crusher and recycling the concrete on hand, and we find a huge cost saving is to be had. For example, we recently spoke to a paving contractor that is dumping 260 tons of concrete a month.

Here's a breakdown of his current costs:

- 80 man hours x $20 = $1,600

- Dump trailer rental = $250

- Trailer insurance = $100

- Fuel = $300

- Dumping costs = $2,000

- Base material costs = $2,500

Total = $6,750

For this use case, we recommended a small, mobile tracked crushing unit that can break down 34 tons of concrete an hour. This is more than enough for the material requirements and can easily be taken to almost any site with its 10'1" x 4'9" transport footprint.

Here's how the costs work out with this crusher:

- Monthly crusher finance = $1,400 (starting cost per month, business profitability dependent)

- Dump trailer rental = $0

- Machine insurance = $450

- Fuel = $20 (1/4 gallon per hour crushing)

- Dumping costs = $0

- Base material costs = $0

Total = $1,870

This means by crushing their own concrete, this contractor could be saving almost $5,000 per month!

Those numbers don’t include the additional profit from reselling recycled concrete aggregate (RCA). Once crushed and screened, RCA typically sells for $5–$15 per ton depending on region and quality. That means the more you produce, the more you can offset machine costs while building a steady secondary income stream.

And this is before we even start to talk about the possibility of crushing waste concrete for other people. Once the concrete is crushed, screened, and made into a highly usable aggregate, it will have a retail value of $15 USD to $5 USD per ton (depending on your location and buyer).

Some contractors even create partnerships with local recycling centers, landscapers, and ready-mix suppliers, supplying them with clean, graded RCA. This keeps the recycled material circulating within the construction industry, strengthening local supply chains and advancing circular economy practices.

What about permits and restrictions?

Before you start recycling concrete on-site, it’s important to check local regulations. Some areas require permits for crushing operations, especially if you're working near residential zones or generating dust and noise. You may also need approval for storing large piles of recycled material or operating heavy equipment on-site. Always contact your city or county permitting office to understand the rules in your area. Taking care of this up front helps avoid fines, shutdowns, or project delays.

Currently, within the United States (depending on the state's requirements), it is a legal obligation for contractors to properly dispose of concrete waste. The cost of renting a 25-yard construction skip is approximately $500 USD without permits and taxes.

Environmental agencies may also require dust suppression systems or noise mitigation plans as part of your operation. Setting up your own recycling process not only ensures compliance but also positions your business as a sustainability leader in your region.

Would it be cheaper to rent a crusher?

Renting a crusher is also an option if you want to test the waters before buying a machine. But beware, as most of our customers that are already renting pay about 3x the amount to rent a similar machine than the monthly payments of purchasing.

In fact, the average contractor we speak to is spending roughly $12k/month to rent a midsized mobile crusher. Meanwhile, our mobile crusher range can be purchased for between $1,400 and $4,700 per month (plus you actually own the machine).

So really the choice is simple: pay to dispose of your old concrete OR recycle and reuse the product, saving money on material purchasing costs or selling the recycled aggregate and adding an additional revenue stream to your business.

Renting may work for short-term projects, but ownership delivers better long-term ROI—especially if you generate concrete waste regularly. Owning a crusher gives you flexibility to crush on demand, reduce downtime, and respond to seasonal workloads without external scheduling constraints.

Where to start with crushing and recycling concrete

So you think recycling concrete sounds like a good option for your business? It could save or even make your business a lot of money!

Great! Why wouldn't you want to recycle concrete with all the obvious financial benefits? By recycling concrete, we can generate a new income stream within a business, reduce its costs, and at the same time upcycle old products that would normally be disposed of.

To begin recycling concrete:

- Assess Material Availability: Ensure a steady supply of concrete waste from demolition or construction projects.

- Choose the Right Equipment: Select crushers and screeners that match your production needs and budget.

- Understand Local Regulations: Comply with environmental and zoning laws related to on-site recycling.

- Market Your RCA: Identify potential buyers in construction, landscaping, and municipal sectors.

We have a team of highly experienced experts in concrete processing and recycling, alongside a huge range of equipment to match every budget and use case.

If you want to get started with recycling concrete, reach out today to speak directly with one of our material experts about your business and material application.

To maximize profits, start by evaluating your current disposal costs and material usage. Contractors who process between 100–300 tons per week often see payback in less than a year. Integrating screening equipment allows you to produce multiple sizes of aggregate, expanding your customer base and increasing throughput.

FAQs: Recycling Concrete for Profit

Is it legal to crush concrete on-site?

In most areas, yes, but you may need permits depending on your location, job size, and proximity to residential zones. Always check with your local municipality or environmental agency before starting.

What kind of equipment do I need to recycle concrete?

At minimum, you'll need a jaw crusher for breaking down large slabs and an optional impact crusher or screener if you want to sort material into different sizes. Compact, tracked crushers are ideal for contractors moving between sites.

You can also integrate conveyors and magnets for a complete mobile concrete recycling system—handling everything from raw demolition waste to clean, reusable RCA.

Can I reuse concrete with rebar in it?

Yes. Most jaw crushers can handle rebar. Machines with a built-in magnet will help separate metal from the crushed product. Removing rebar after crushing ensures cleaner, more marketable aggregate.

Crushers equipped with magnetic separators or metal detection systems help prevent contamination, producing higher-quality recycled concrete suitable for reuse in new concrete mixes and structural fill.

How much money can I save by recycling concrete?

Contractors who recycle on-site often save $40–$60 per ton by avoiding landfill fees, trucking, and new material purchases. That can add up to thousands of dollars per job.

Over time, these savings compound, especially for contractors handling consistent demolition or site prep work. Concrete recycling not only boosts profitability but also helps lower your project’s carbon footprint.

Can I sell crushed concrete?

Absolutely. Recycled concrete aggregate (RCA) can be sold for road base, backfill, or drainage material. Prices vary by region, but it's not uncommon to sell RCA for $5–$15 per ton.

Some buyers—such as municipalities and ready-mix plants—require recycled aggregate that meets ASTM or DOT gradation standards. By maintaining consistent quality, you can tap into larger commercial and infrastructure markets.

Next steps

Concrete recycling represents one of the most practical and profitable steps toward sustainable construction. It reduces waste, conserves raw materials, and turns old concrete into new value. Contractors who adopt on-site crushing aren’t just improving their bottom line, they’re helping build a more efficient and environmentally responsible construction industry.