Concrete Pumps: A Complete Guide for Contractors, Shotcrete Crews, and Large-Scale Concrete Operations

Concrete pumps are essential equipment for moving concrete efficiently across job sites, reducing labor, increasing productivity, and improving placement accuracy. Whether you run a commercial construction crew, a shotcrete operation, or a ready-mix service, concrete pumps offer faster delivery, higher pressure capability, and more consistent concrete placement than manual methods or wheelbarrows.

From trailer-mounted line pumps to truck-mounted boom pumps, contractors across North America rely on pumps to reach difficult areas, support large-scale pours, and maintain steady concrete flow directly from the mixer truck.

What a Concrete Pump Does

A concrete pump transfers concrete from a mixer truck through a system of pipes, hoses, or articulated booms. The pump uses hydraulic pressure and piston pumps to move concrete mixes precisely where they are needed, even when the placement is elevated, far from the road, or obstructed by structures.

Concrete pumps are used to:

- Place concrete over long distances

- Reach elevated locations

- Pump high-volume or high-pressure mixes

- Support residential, commercial, and infrastructure projects

- Improve flow to forms, foundations, and restricted areas

- Transport concrete from mixer trucks directly to placement zones

Concrete pumping reduces labor requirements, eliminates bottlenecks, and creates consistent placement even on complex job sites.

Types of Concrete Pumps

Contractors choose pumps based on reach, pressure, and the type of concrete mix needed for the project.

Line Pumps (Trailer-Mounted Concrete Pumps)

Line pumps move concrete horizontally or at modest vertical heights through hoses and pipe sections. They are often mounted on trailers and towed by work trucks. Line pumps are ideal for patios, driveways, mid-size pours, and job sites with limited access. They handle a wide range of concrete mixes, including mixes with larger aggregate.

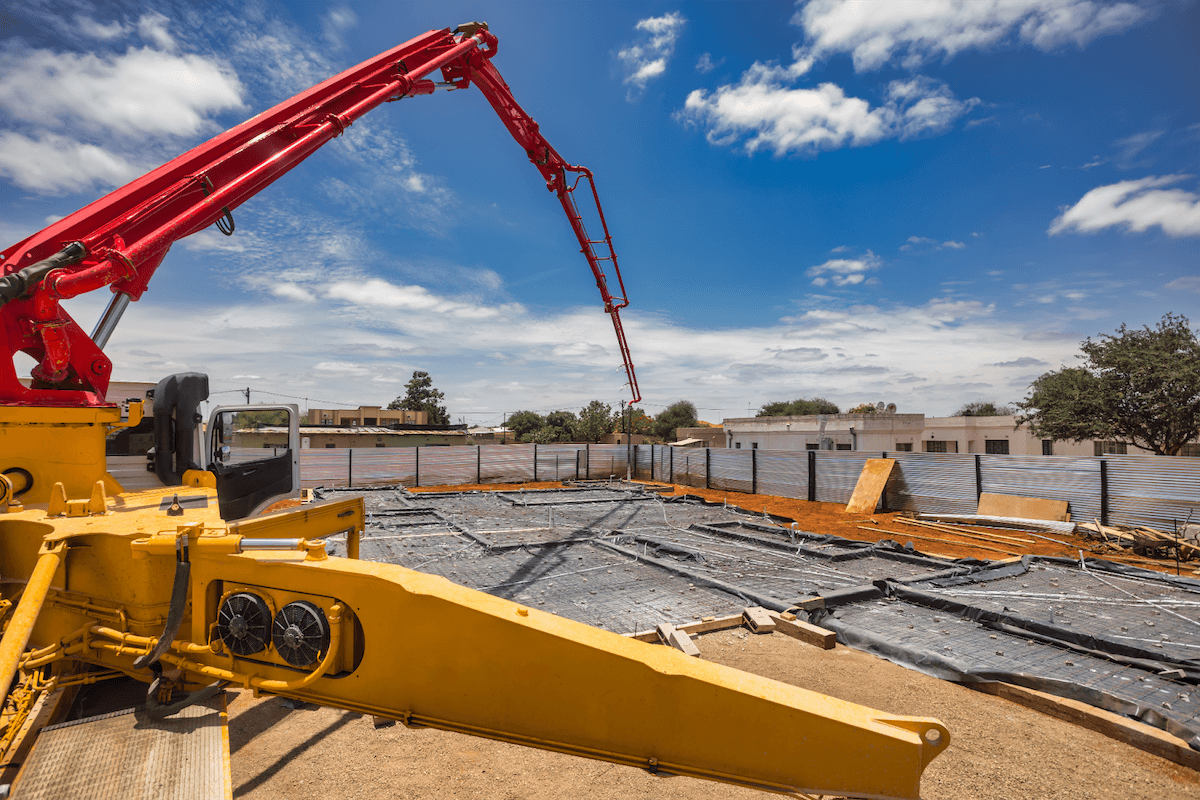

Boom Pumps (Truck-Mounted Concrete Boom Pumps)

Boom pumps include an articulating boom mounted to a truck chassis, allowing operators to place concrete at extreme vertical and horizontal distances. Boom pumps support large-scale commercial pours, multi-story buildings, and heavy infrastructure work. They are known for high volume output, extended reach, and fast setup times.

Shotcrete Pumps

Shotcrete applications rely on high-pressure pumps capable of delivering consistent pressure for structural and slope stabilization projects. Shotcrete pumping requires precise control and durable components to handle dense, high-pressure mixes.

High-Pressure and High-Volume Pumps

Heavy-duty piston pumps deliver high-pressure capability for long-distance pumping. High-volume pumps support continuous pours and larger commercial sites that require uninterrupted supply from mixer trucks.

Key Components of a Concrete Pump

Concrete pumps include several critical components that determine performance, durability, and mix compatibility.

Hopper

The hopper receives concrete from the mixer truck. Its design prevents clogging, supports flow, and minimizes aggregate separation.

Piston Pump System

Hydraulic pistons move concrete through the pump system. High-quality piston systems improve pressure, reduce wear, and support demanding mix types.

Pipes and Hoses

Pipe and hose configuration determines reach, output, and flow. Proper pipe diameter ensures compatibility with mix design and aggregate size.

Boom System (for Boom Pumps)

The articulated boom allows precise placement over obstacles and at elevated locations. Boom length varies by model and determines maximum reach.

Hydraulics and Controls

Hydraulic systems power pump pistons, stabilizers, and boom articulation. Reliable controls ensure smooth operation, safety, and consistent output.

Chassis and Mounting System

Truck-mounted pumps rely on commercial trucks such as Freightliner chassis, providing mobility and stability for large job sites.

Applications Across Concrete Construction

Concrete pumps support a wide range of commercial, residential, and infrastructure operations.

Commercial Construction

Boom pumps deliver concrete to floors, decks, slabs, and elevated structures with speed and accuracy.

Residential Foundations

Line pumps move concrete through tight residential sites for foundations, walls, and patios.

Shotcrete and Slope Stabilization

High-pressure pumps deliver shotcrete mixes for retaining walls, tunnels, pools, and geological reinforcement.

Infrastructure Projects

Concrete pumps support bridges, highways, dams, and other large-scale infrastructure requiring long-distance pumping.

Industrial Facilities

Pumps deliver durable concrete mixes inside plants, warehouses, and manufacturing facilities where direct access is limited.

Benefits of Using a Concrete Pump

Concrete pumps provide significant value across multiple construction sectors:

- Faster concrete placement

- Reduced labor and job site congestion

- Higher operational efficiency

- Ability to pump difficult concrete mixes

- Greater accuracy in confined or elevated locations

- Improved safety and reduced material handling

- Consistent flow for large-scale pours

Pumps improve site productivity by ensuring concrete reaches its destination quickly and cleanly, reducing delays and improving project schedules.

Frequently Asked Questions About Concrete Pumps

What is the difference between a line pump and a boom pump?

A line pump uses hoses and pipes for horizontal pumping, ideal for small and mid-size projects. A boom pump uses an articulated boom for long reach and high-volume placement.

Can a concrete pump handle large aggregate?

Yes. Many line pumps and trailer pumps can handle larger aggregate mixes, depending on pipe diameter and pump design.

How far can a concrete pump reach?

Boom pump reach depends on boom length, while line pumps depend on pipe length and pump pressure. Modern pumps can reach hundreds of feet horizontally and vertically.

What type of pump is used for shotcrete?

High-pressure piston pumps are used for shotcrete to maintain consistent pressure and flow.

Does using a concrete pump reduce labor costs?

Yes. Pumps significantly reduce manual labor and streamline placement, resulting in faster, safer job site operation.