Conveyor Systems: The Backbone of Material Handling Across Recycling, Aggregates, and Industrial Operations

Introduction

In almost every heavy material handling business, conveyors are where you unlock real efficiency. Whether you are running a recycling line, feeding a crusher, or loading out finished product, conveyor systems replace the most expensive part of moving material: loaders, fuel, and operators.

On average, a well-designed conveyor setup can cut the cost of moving material by 80–90 percent compared to doing the same job with a loader. Instead of buying a 300,000 dollar loader, burning diesel all day, and paying an operator plus ongoing maintenance, a conveyor lets you move that same tonnage with a fraction of the operating cost. Over a season, that gap becomes a meaningful difference in profit per ton.

For recycling facilities, quarries, and industrial plants, conveyors also do more than reduce costs. They stabilize throughput, protect workers from repetitive and high-risk tasks, and create a predictable production line that is easier to automate and scale. That is why so many Machinery Partner customers see conveyors as the backbone of their material handling strategy rather than an accessory.

What Conveyor Systems Do

Conveyors are engineered systems that transport materials from one point to another using continuous belts, rollers, chains, or pneumatic flow. In heavy-duty applications, they are built to carry a wide range of materials like aggregate, scrap metal, compost, or packaged goods with minimal manual intervention.

In recycling and waste operations, conveyors streamline how materials move through shredders, sorters, and balers. In aggregate production, they link crushers and screeners to stockpiles, keeping material flow consistent. And in manufacturing, automated conveyors transport parts, pallets, and finished goods between workstations to maintain a smooth production rhythm.

Conveyors are not just about movement. They support sorting, elevating, weighing, and even cooling materials as part of a larger material-handling ecosystem. Modern automation solutions now integrate conveyors with optical sorters, sensors, and robotics, helping companies achieve high throughput and consistent performance.

Common Conveyor System Types

Because each operation handles different materials, conveyor systems are built in many configurations. Understanding the types available helps buyers match equipment to the material flow, layout, and operational goals of their facility.

Belt Conveyors

The most common type, belt conveyors use a continuous belt stretched over pulleys to move materials. They are ideal for transporting bulk materials such as gravel, compost, or shredded waste. The belt can be made of rubber, PVC, or fabric, with varying ply thicknesses depending on load and abrasion resistance.

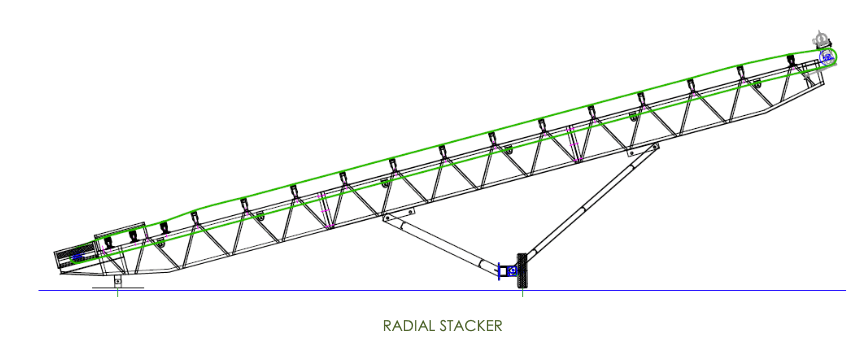

Several variations exist: truss conveyors (rigid frame for long spans), channel conveyors (compact for shorter runs), and radial stackers, which rotate to form stockpiles without repositioning the machine. These designs are standard in aggregate yards, quarries, and recycling centers that need reliable mobility and stacking capability.

Roller Conveyors

Roller conveyors use a series of rollers mounted on frames to move products or totes. They can be gravity-driven for simple transport or motorized for automated lines. Roller systems are common in distribution centers and manufacturing facilities, especially where cartons, pallets, or containers are moved between stages of production or packaging.

Chain Conveyors

Chain conveyors use interlinked chains to pull heavy or irregular loads that belts cannot easily handle. They are often found in automotive, metal recycling, and pallet-handling applications. Their rugged design and high torque make them ideal for environments that demand continuous movement under extreme load.

Overhead Conveyors

Overhead conveyors transport materials suspended from a chain or trolley track. They save valuable floor space and are often used in manufacturing plants or painting lines where items need to move through work zones without ground-level obstruction. Their integration with automation systems allows for controlled routing and queuing of parts in production environments.

Modular and Pallet Conveyors

In automated warehouses and production facilities, modular and pallet conveyors provide flexible and reconfigurable layouts. Modular systems use linked plastic sections that can curve and elevate, while pallet conveyors handle heavier, discrete items on fixed carriers. Both systems integrate easily with sortation and robotics to improve efficiency and reduce product damage.

Specialized Stackers and Grasshopper Conveyors

For mobile and aggregate operations, stackers and grasshopper conveyors provide portable flexibility. Stackers extend and pivot to build conical stockpiles without loader assistance, while grasshopper conveyors connect portable machines like crushers or screeners to create a temporary material flow line. Both are critical in quarrying and C&D recycling where setup time and mobility matter.

Conveyor Structures and Layouts

The structure of a conveyor is what gives it strength, span, and flexibility on site. It is helpful to separate the structural members from the “type” of conveyor, since many of the same components show up across different configurations.

Truss sections are the core building blocks of many longer conveyors. Each truss is a welded lattice frame that can be pinned or bolted together in series. For example, four 20-foot trusses can be combined to create an 80-foot conveyor. Truss construction provides the rigidity needed to span longer distances without excessive supports or deflection, which is why it is standard on stackers and yard conveyors.

Channel frame conveyors use formed steel channels instead of open truss sections. They are typically used for shorter runs, transfer points, or where frequent maintenance access is important. Channel designs are lighter and more compact, which makes them a good fit indoors or in tight plants.

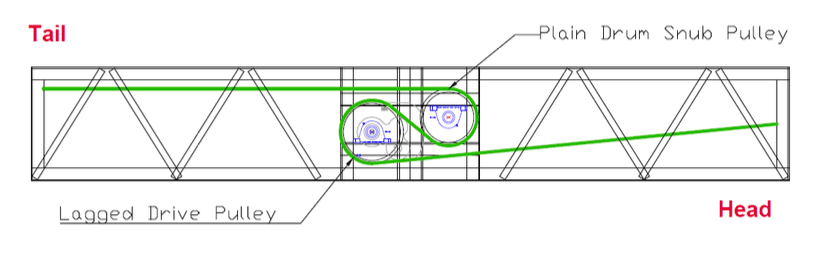

At each end of the conveyor, the head and tail sections carry the key mechanical components. The head houses the drive assembly, including the motor, speed reducer, belt guard, and lagged head pulley that provides traction on the belt. The tail supports the tail pulley, guarding, and load zone where material is dropped onto the belt. On longer conveyors, gravity take-up systems are added to maintain consistent belt tension as the belt stretches during operation.

Grasshopper conveyors are short, portable sections that bridge gaps between machines or help build temporary layouts. They use similar truss or channel structures, but are designed to be repositioned frequently as a site changes.

Radial stackers are a specific conveyor type that combines a truss or channel structure with a rotating base. The conveyor can pivot in an arc to build large circular or kidney-shaped stockpiles without moving the feed machine. This layout is common in aggregates and recycling because it maximizes ground usage and minimizes loader time spent reshaping piles.

Together, these structural elements let you design conveying systems that fit the site: long-span stockpiling, compact in-plant transfer, or reconfigurable mobile lines that follow mobile crushers and screeners.

Core Conveyor Components Explained

Understanding the anatomy of a conveyor system is key to selecting the right equipment and keeping it running efficiently. Each component plays a specific role in supporting throughput, durability, and safety.

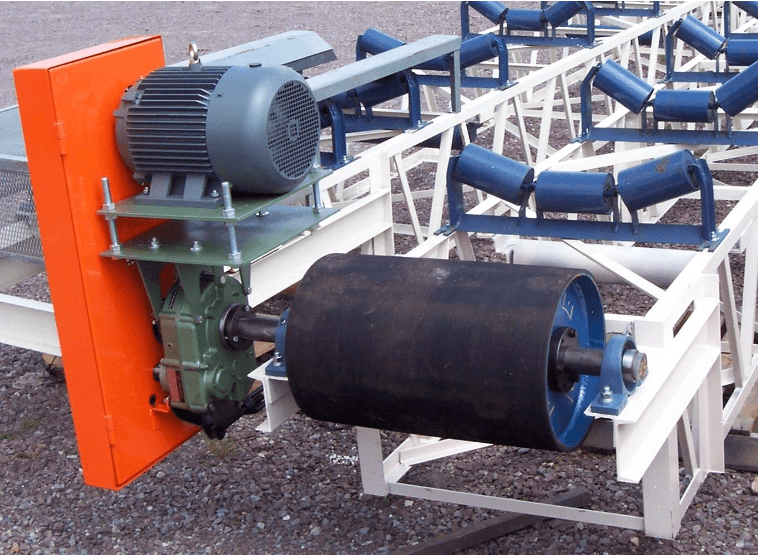

Head and Tail Assemblies

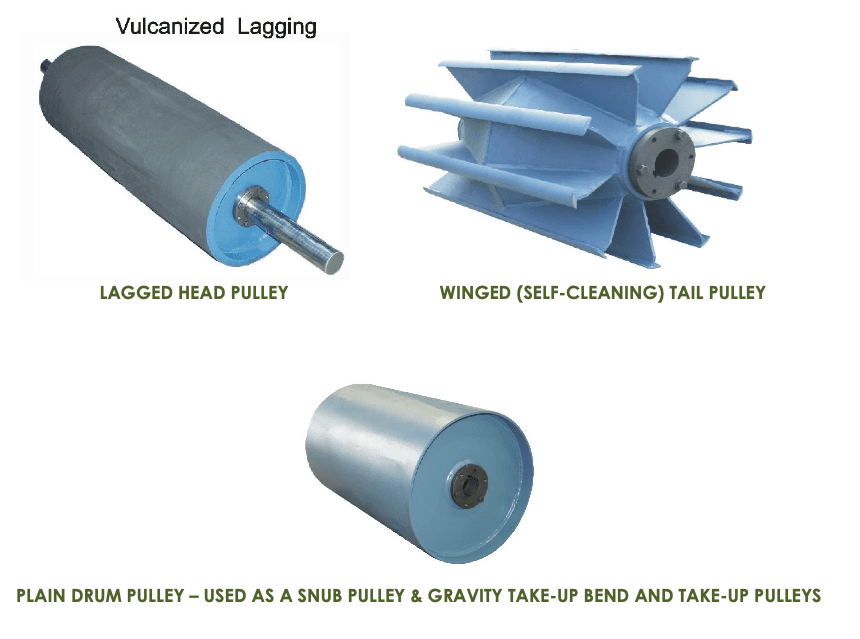

The head section houses the drive assembly. This assembly is comprised of the motor, speed reducer, belt guard, and bushings and they are responsible for propelling the belt. Lagged head pulleys improve traction, while winged tail pulleys help self-clean and release trapped material. Larger conveyors often include gravity or tubular take-ups in the tail section to maintain belt tension over long runs.

Pulleys and Bushings

Pulleys come in various styles, such as lagged head pulleys for traction or plain drum pulleys for snub and bend functions. QD, XT/HE, and Dodge taper-lock bushings ensure a secure fit between the pulley and shaft, simplifying maintenance and replacement.

Bearings and Take-up Assemblies

Pillow block bearings, flange bearings, and take-up bearings support the rotating shafts and help align the belt path. Take-up bearings, often in a square-slot design, allow for adjustment as the belt stretches during operation.

Idlers and Rollers

Idlers support the conveyor belt along its length and help maintain its shape. Common types include troughing idlers (20°, 35°, or 45°), return idlers, and impact idlers used at loading zones. Top and bottom training idlers automatically align the belt, reducing wear and minimizing spillage. Impact beds or rubber disc returns add extra protection in high-load zones.

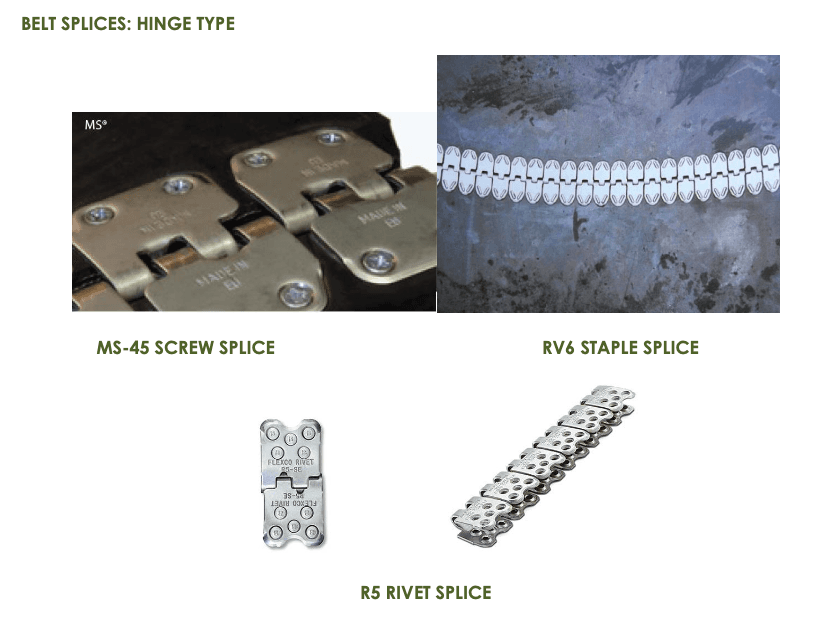

Belting and Splicing

Conveyor belts vary in ply count (two, three, or four layers) with top covers ranging from 3/16 to 3/8 inches. Heavy-duty applications may use rubber or fabric belts with V-cleat or chevron patterns for better material grip on inclines. Belts are joined using hinge, screw, staple, rivet, or rigid plate splices, each offering different strengths for maintenance speed versus load-bearing capacity.

Drive Systems and Speed Reducers

Motors, typically in the 1–150 HP range, are coupled to speed reducers that provide torque and regulate belt speed. Proper sizing ensures the belt maintains consistent motion without strain. Many modern systems use variable frequency drives (VFDs) to fine-tune speed and improve energy efficiency.

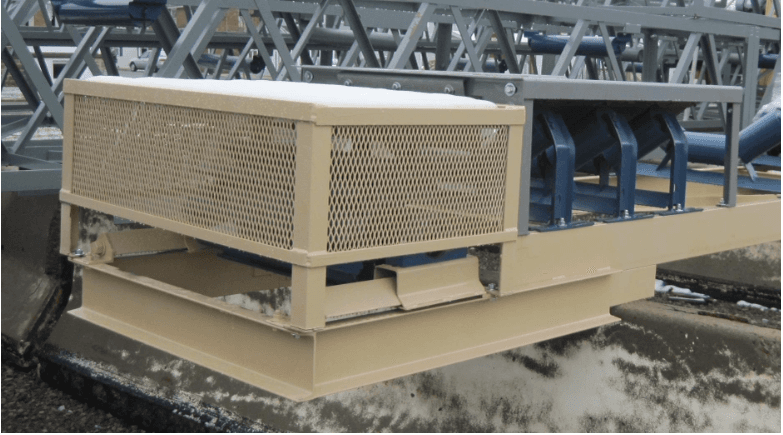

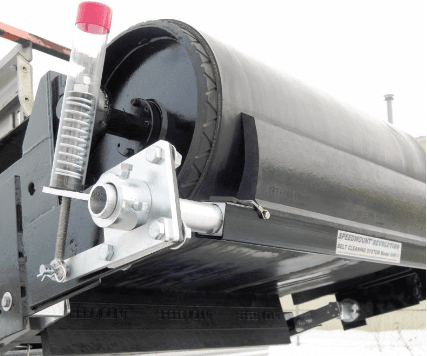

Safety and Accessory Components

Power travel kits, catwalks, belt scrapers, and guards are essential for safe operation and maintenance. These optional features also reduce product buildup and improve belt longevity.

Conveyor Applications Across Industries

Recycling and Waste Management

Conveyors keep material moving through shredders, sorters, magnets, and balers. In transfer stations or MRFs, modular conveyors simplify reconfiguration as material streams change. For heavier waste or scrap metal, chain conveyors and heavy-duty truss systems are preferred for durability and torque.

Aggregates and Construction

In quarries and C&D recycling sites, conveyors connect crushers, screeners, and stockpiles. Truss and radial stacker designs dominate here for their strength and mobility. A radial stacker allows operators to build stockpiles efficiently without repositioning loaders, saving both fuel and labor.

Manufacturing and Industrial Facilities

Factories and logistics hubs use automated conveyors for pallets, totes, and product handling. Belt or roller conveyors form the backbone of assembly lines, while overhead conveyors free up floor space for equipment and workers. Pneumatic or chain conveyors handle bulk materials, powders, or heavy parts with precision and minimal product damage.

Benefits of Modern Conveyor Systems

Automation and Efficiency

By integrating conveyors with automation systems, facilities reduce manual labor and human error. Material moves seamlessly between machines, creating predictable workflows and faster throughput.

Energy Efficiency

Modern conveyor drives and belt designs use energy-efficient motors and lightweight materials. When paired with VFDs, systems can adjust speed dynamically to match load demands, reducing power use and wear.

Safety and Ergonomics

Automation reduces the need for heavy lifting or repetitive motion, improving worker safety. Catwalks and enclosed guarding systems protect operators from moving parts.

Cost Reduction

Though conveyors require an upfront investment, they deliver long-term savings through labor reduction, consistent operation, and fewer maintenance interruptions.

Scalability and Modularity

Modular conveyors can expand with your operation. Facilities can add new sections, sorters, or diverters without redesigning the entire system. This is critical for businesses scaling production or diversifying materials.

Maintenance and Downtime Prevention

Keeping conveyors operating at peak performance depends on regular inspection and preventative maintenance.

- Inspect belts for wear, cracks, or fraying edges.

- Check pulleys and bushings for misalignment or vibration.

- Clean impact zones and scrapers to avoid buildup.

- Monitor bearings for overheating and lubricate as recommended.

- Replace worn idlers to prevent belt tracking issues.

Preventative maintenance programs reduce costly stoppages and extend equipment life. Many Machinery Partner customers set up quarterly service checks or use connected monitoring systems to predict component wear before failure.

Example Conveyors Available from Machinery Partner

Machinery Partner carries a focused lineup of conveyors and stackers that pair directly with crushers, screeners, and shredders to create complete material handling systems.

Portable Stackers radial conveyors are built for stockpiling and load-out in aggregates, demolition waste, and organics. Models like the R2440, R3640, and R3660 are designed to move up to 200 tons per hour, building tall, wide stockpiles without constantly repositioning your crusher or screener.

Barford tracked stacker conveyors, such as the TR3032, TR8036, and TR8048, are ideal for mobile crushing and screening setups. They run on tracks so they can follow your plant around the site, reduce the need for loader shuttle runs, and keep material flowing from the crusher or screener straight to stockpile.

Beyond these flagship lines, Machinery Partner also offers other conveyor solutions across multiple material applications and categories, including gravel, sand, mulch, and demolition waste. This makes it possible to design a conveying system that matches your material, site layout, and production goals, instead of trying to force a one-size-fits-all machine into your workflow.

Explore Machinery Partner’s conveyor equipment inventory to see full specifications, throughput ratings, and lead times.

Frequently Asked Questions About Conveyor Systems

What are conveyor systems used for?

Conveyor systems are used to move materials efficiently across production lines, warehouses, and recycling plants. They streamline workflow, reduce manual labor, and help operators achieve high throughput. In industries like aggregates and recycling, conveyors transport heavy loads such as stone, scrap metal, or waste. In manufacturing or e-commerce, they handle cartons, totes, and pallets through automated systems designed to optimize order fulfillment.

What are the main types of conveyor systems?

The most common conveyor types are belt conveyors, roller conveyors, chain conveyors, overhead conveyors, and pallet conveyors. Belt conveyors move bulk materials like aggregates or compost, while roller conveyors excel in warehousing and packaging. Chain conveyors carry heavy-duty loads, overhead conveyors save floor space, and pallet conveyors are built for high-performance material handling in automated environments.

How do automated conveyor systems improve productivity?

Automated conveyor systems increase throughput by integrating sensors, sorters, and robotics into material handling workflows. They reduce delays between machines, optimize energy efficiency, and allow continuous product movement without manual intervention. For high-volume operations, automation helps maintain consistent flow, minimizes product damage, and improves overall operational efficiency.

What industries use conveyor systems?

Conveying systems are vital across aggregates, recycling, warehousing, manufacturing, automotive, food processing, and e-commerce distribution centers. They move materials safely, streamline production, and create ergonomic workflows that reduce strain on workers while maintaining high performance under heavy-duty conditions.

How do conveyors help reduce labor costs?

By automating repetitive material handling tasks, conveyors significantly cut manual labor requirements. Workers can focus on skilled or supervisory tasks while automated systems handle continuous transport of pallets, totes, or cartons. This leads to lower labor costs, faster production cycles, and a more efficient use of personnel across the operation.

What is a modular conveyor system?

Modular conveyor systems are built from interchangeable sections or modules that can be added, removed, or reconfigured as operations change. They are common in automated warehouses, where production lines and product flows often evolve. Modular design makes maintenance easier, reduces downtime, and provides a cost-effective way to scale operations.

What should I consider when choosing a conveyor solution?

Key factors include the type of material being moved, load weight, throughput goals, available space, and power requirements. You should also consider the balance between automation level, energy efficiency, and total cost of ownership. Selecting the right conveyor equipment ensures optimized workflow and reduced maintenance over time.

How can conveyors be integrated into automated warehousing?

In distribution centers, conveyors integrate with sortation systems, pallet conveyors, and automated guided vehicles (AGVs). They connect storage zones to packaging and shipping stations, maintaining a smooth, high-throughput production line that supports rapid e-commerce fulfillment.

What makes a conveyor system energy-efficient?

Energy-efficient conveyors use lightweight materials, low-friction rollers, and variable frequency drives (VFDs) that adjust motor speed to match load demand. This reduces wasted power and extends component life while maintaining the same level of throughput.

How do pneumatic conveyors differ from mechanical ones?

Pneumatic conveyors use air pressure or vacuum to move materials through tubes, making them ideal for lightweight or powdered materials. Mechanical conveyors, such as belt, roller, and chain systems, use physical components to transport items and are better suited for heavy loads and continuous production.

What causes product damage on a conveyor line?

Improper belt tension, misaligned rollers, or excessive speed can lead to product damage. Using the right conveying system for material type, maintaining clean impact zones, and incorporating sortation systems that handle items gently all help prevent issues.

Final Thoughts

Whether you’re moving crushed stone, shredded waste, or manufactured goods, conveyor systems are the core of modern material handling. They enhance throughput, improve safety, and bring consistency to every part of production.

For operations that span recycling, aggregates, and manufacturing, the right conveyor solution is both a productivity tool and a long-term cost saver. Machinery Partner helps companies design and source systems that match their materials, production goals, and budget, ensuring efficiency from the first load to the last.