Tree Cardboard and Wood Waste Recycling: Throughput, Costs, and Equipment Choices

Tree cardboard and wood waste recycling is a common challenge for distribution centers, construction sites, recycling yards, and municipal operations that handle packaging and wood products at scale. Cardboard, pallets, crates, and clean wood waste often enter the waste stream together, creating volume quickly and driving up hauling and disposal costs if left unmanaged.

Recycling these materials on site or at centralized facilities allows operators to reduce disposal expenses, improve material recovery, and maintain predictable waste handling workflows.

Materials Included in Tree Cardboard and Wood Waste Streams

Tree cardboard includes corrugated boxes, cartons, and fiber-based packaging derived from wood pulp. Wood waste includes pallets, crates, dunnage, offcuts, and clean dimensional lumber. While these materials differ in density and recycling pathways, they are frequently generated together in logistics, construction, and municipal environments.

Effective recycling programs treat them as parallel streams rather than mixed waste. Cardboard is typically compacted or baled, while wood waste is reduced in size through shredding or grinding.

Why These Materials Accumulate So Quickly

High-volume facilities generate cardboard and wood waste continuously. Distribution centers process inbound and outbound shipments daily. Construction sites discard pallets and packaging throughout a project. Municipal programs aggregate cardboard and wood debris from multiple collection routes.

Without size reduction or compaction, loose material consumes space rapidly. Dumpsters fill before scheduled pickups, leading to overflow, emergency hauls, and higher disposal costs. Mixed loads are especially expensive because they limit downstream recycling options.

Recycling systems address these issues by reducing volume and separating materials early in the process.

Machines Used for Cardboard and Wood Waste Recycling

Recycling cardboard and wood waste at scale requires a combination of compaction and size-reduction equipment. The exact setup depends on material volume, available space, and whether the goal is disposal cost reduction or material resale.

Industrial Compactors

Compactors are commonly used to reduce the volume of loose cardboard and mixed packaging. By compressing material directly into a container, compactors significantly reduce hauling frequency and keep docks and waste areas clear. They are often the first step for facilities focused on lowering disposal costs without managing bale logistics.

Balers

Balers are used when cardboard is being recycled or sold rather than disposed of. These machines compress cardboard into dense, uniform bales that are easier to store, transport, and market. Balers are common in distribution centers and recycling facilities that generate consistent, clean cardboard streams.

Industrial Shredders

Shredders are used to process pallets, crates, and clean wood waste. Low-speed, high-torque shredders break down bulky wood material into manageable sizes while handling nails and fasteners with controlled wear. Shredding reduces volume and prepares wood waste for downstream reuse or disposal.

Wood Grinders

Grinders are used when finer output is required, such as for mulch, compost feedstock, or biomass applications. Compared to shredders, grinders produce more uniform material and higher throughput, making them suitable for facilities with defined end-use requirements.

Conveyors and Material Handling Equipment

Conveyors are often used to connect compactors, balers, shredders, and grinders into a continuous workflow. They reduce manual handling, improve safety, and allow recycling systems to operate more efficiently as material volume increases.

Typical Throughput for Cardboard and Wood Waste Processing

Throughput depends on material type and equipment selection, but realistic industrial ranges include the following.

Cardboard compactors and balers commonly process 1 to 5 tons per hour, depending on feed method and material consistency. High-volume distribution centers often exceed this during peak shifts.

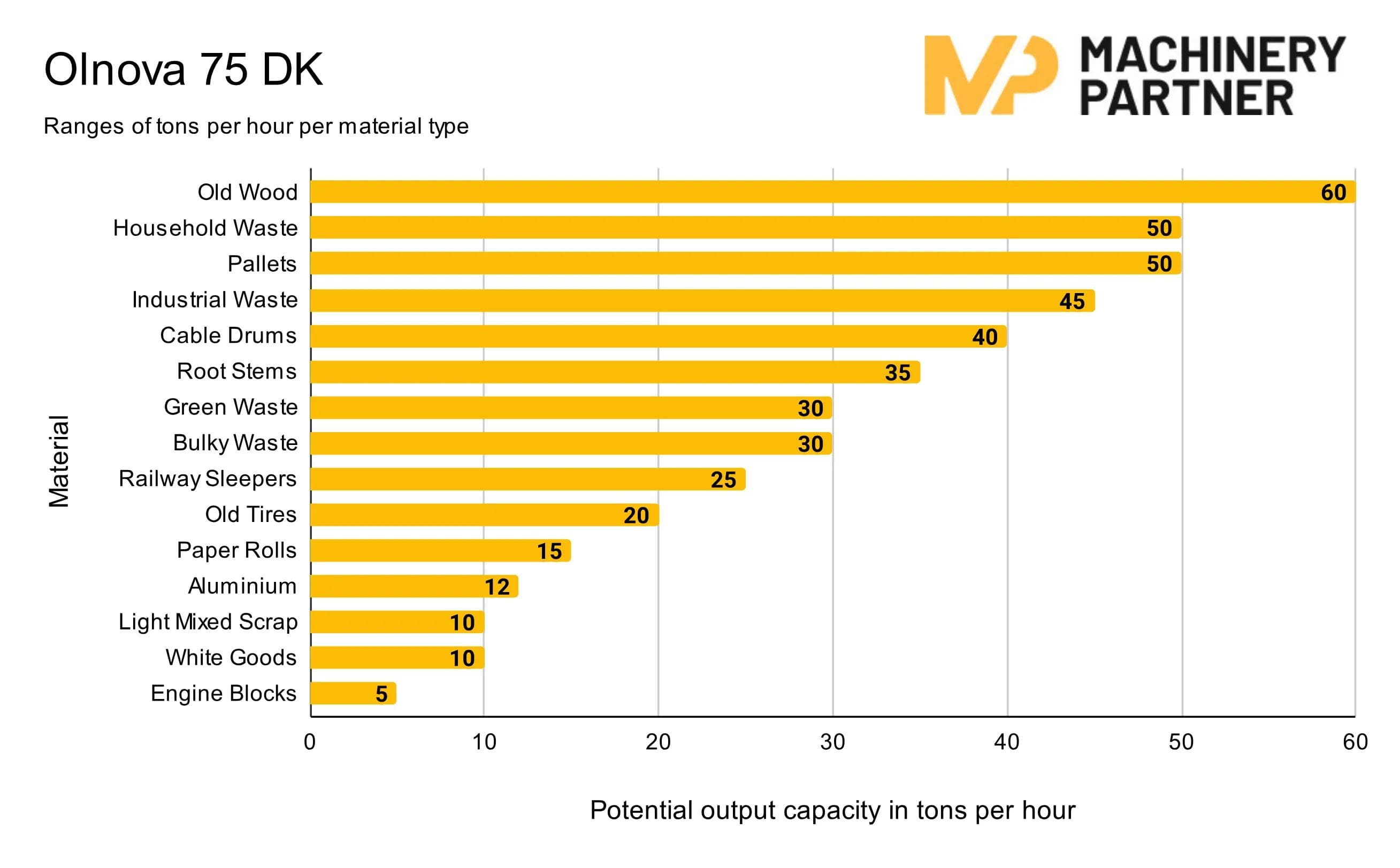

Industrial wood shredders and grinders typically process 5 to 30 tons per hour of pallets and clean wood waste. Throughput varies based on pallet condition, nail content, and desired output size.

At these rates, facilities can reduce loose material volume by 60 to 80 percent, dramatically lowering hauling frequency.

Equipment Used in Tree Cardboard and Wood Waste Recycling

Machinery Partner customers typically use a combination of compaction and size-reduction equipment to manage these streams effectively.

Cardboard is handled using industrial compactors or balers. These machines compress loose boxes into dense bales or containers that are easier to store and transport. For facilities focused on disposal cost reduction rather than resale, stationary or vertical compactors are common. Where resale or recycling revenue is a priority, balers are used.

Wood waste is processed using industrial shredders or grinders. Low-speed, high-torque shredders are commonly used for pallets and crates because they handle nails and mixed material with controlled wear. Grinders are selected when finer output is required for mulch, compost feedstock, or biomass applications.

This combination allows facilities to process both material streams efficiently without relying on mixed-waste hauling.

Cost Impact and Savings Potential

The primary financial benefit comes from avoided disposal. Facilities that shift cardboard and wood waste out of mixed dumpsters often reduce hauling frequency by 50 percent or more.

Cardboard recycling may generate direct revenue or at least offset hauling costs when material quality is consistent. Wood waste recycling reduces landfill tipping fees and may produce material suitable for resale or internal reuse.

Facilities that previously relied on frequent mixed-waste pickups often see annual savings in the tens of thousands of dollars, depending on volume and local disposal rates.

Operational and Safety Benefits

Recycling improves site organization by reducing loose material around docks, staging areas, and work zones. Compacted cardboard and processed wood waste are easier to store and safer to handle.

Reduced clutter lowers fire risk, improves traffic flow, and allows crews to focus on production rather than waste management. Predictable waste handling also reduces unplanned interruptions caused by full dumpsters or emergency pickups.

Environmental and Compliance Considerations

Recycling tree cardboard and wood waste supports landfill diversion goals and sustainability reporting. Processing wood waste into secondary products reduces demand for virgin material and lowers overall environmental impact.

Many municipalities and large commercial operators now track recycling rates as part of compliance and ESG initiatives. Controlled recycling programs also reduce the risk of environmental violations related to unmanaged waste piles.

When Recycling Becomes the Better Option

Manual handling and mixed-waste hauling may work at low volumes. Once material volume increases or disposal costs rise, recycling becomes the more stable and economical approach.

When waste handling begins to interfere with operations, equipment-based recycling is typically the inflection point.

Frequently Asked Questions About Tree Cardboard and Wood Waste Recycling

What materials are typically recycled together in these programs?

Corrugated cardboard, pallets, crates, dunnage, and clean wood waste are commonly processed as parallel recycling streams.

Can cardboard and wood waste be processed with the same equipment?

They are usually handled with different machines due to density and output requirements, but they are often managed within the same recycling workflow.

How much volume reduction can recycling provide?

Facilities commonly see 60 to 80 percent volume reduction through compaction and shredding.

Does recycling reduce hauling costs?

Yes. Reduced volume leads to fewer pickups and lower disposal fees.

What equipment is most commonly used?

Industrial compactors or balers for cardboard, and low-speed shredders or grinders for wood waste.