How to Set Up a Stone Crusher Plant: Equipment, Layout, and Costs

Article updated October 20, 2025

Setting up a successful stone crusher plant means balancing plant design, cost and efficiency. But first, you’ll need to learn how to optimize your crushing setup while choosing the best machinery for your crushing needs. This requires a good understanding of which equipment works best for the type of stone you are crushing. You should also think about what you want your final product to look like, for example, graded 3/4 inch aggregate.

Successful stone crushing starts with matching the right crushing equipment to your material and desired gradation, then sizing each station for your target tph so you can crush materials efficiently with minimal downtime. For hard rock, a heavy duty primary crusher leads the first stage, followed by a screening plant and a secondary cone crusher or impact crusher for fine crushing and a high-quality, on-spec final product.

This blog will explore the stone crusher plant essential equipment, and the best way to set up a plant that works for you.

We will cover primary crushing, secondary crushing, and optional tertiary crushing, plus how conveyor belts, a control system, and wear-resistant parts keep the crushing process stable for road construction, quarry work, and the mining industry.

Find stone crushers for sale at Machinery Partner.

What is a stone crusher plant?

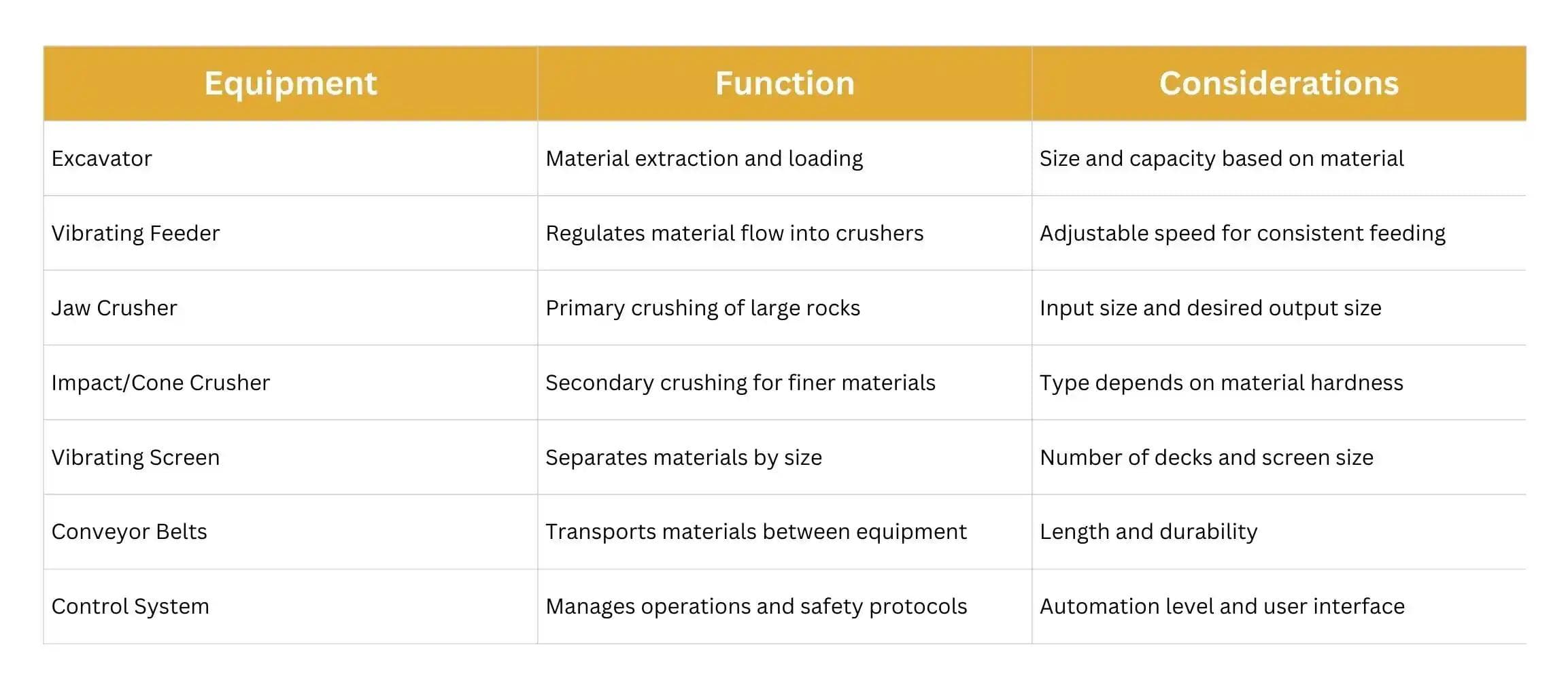

The stone crusher plant consists of a crushing setup of excavators, feeders, primary and secondary crushers and screeners. They all work together to crush stone as efficiently as possible. Conveyors connect everything, moving the crushed material from one station to the next.

In practice, rock crushing flows from feed hopper to primary crushers, across a vibrating screen, then to secondary crushers, with oversize recirculation. The result is smaller pieces in controlled sizes for aggregate, asphalt, or concrete.

Stone crusher plant equipment is divided into two categories:

- Configuration equipment – moves the material between machines and feeds it into the primary crushing equipment before screening.

- Main equipment – is responsible for the actual crushing of the stone. Main equipment often includes a jaw crusher as the primary crusher, a cone crusher or impact crusher as the secondary, and sometimes a VSI crusher for shaping. Configuration typically includes hoppers, grizzly bars, conveyor belts, and stackers to maintain high-capacity flow.

This equipment can be fixed (static) or mobile. Using mobile, tracked equipment allows you to change out, replace or move equipment about a site or between jobs.

A mobile crushing plant lets you process on-site, reduce dump trucks on the haul, and trim operating costs, while static plants excel in very high-speed, high-capacity production environments.

Check out the importance of stone grades & what they are.

How to set up a stone crusher plant

From feeding large material into the plant to primary & secondary crushing and screening - each phase of the stone crushing process needs the right equipment.

Balancing each station prevents bottlenecks. Right-sizing the feeder, crusher, and screening plant to your feed size and desired product size is critical to smooth crushing stages.

Let’s look at each step and the best crushing setup machinery for each task.

Find out all about crushing plants, what they are and how you can set one up.

Step 1: Extraction and Loading

During loading, the material is extracted and fed into the plant, where it moves into the first step of the crushing setup. A large excavator is the perfect machine for extracting large volumes of material and transporting it to a vehicle or conveyor for feeding.

Use a ripper or breaker at the face if boulders exceed the primary’s feed opening. A grizzly can scalp fines to protect the primary and stabilize feed rate. Consistent loading helps the line hold target tph.

A jaw crusher uses a fixed jaw and a moving jaw to compress rock in the crushing chamber, delivering a reliable reduction ratio on hard materials. For extremely abrasive feeds, a gyratory crusher can be an alternative primary with continuous crushing action and uniform product at high capacity.

Step 2: Primary crushing

Next, the material is fed into the primary crusher using a vibrating feeder. Here the stone is broken up and crushed for the first time, usually by a large jaw crusher. Grizzly bars can prevent oversized material from getting into the jaw box and jamming or damaging it. This reduces downtime and helps keep the stone crushing process running. Primary crushers are really important in a stone crushing plant setup as they are able to handle large boulders and can take a lot more wear-and-tear. They also help speed up the crushing process as all the hard work is done before it reaches the next step. Recommended equipment: Omega Tracked Mobile Jaw Crusher

Step 3 – Secondary crushing

At this point, your material is made up of large pieces that have come out of the primary jaw crusher. Conveyors then move the material to a secondary impact crusher, where it can be broken down further into smaller, similar-sized pieces. The output of an impact crusher is great for making graded aggregate. You may also use a cone crusher for this phase in the stone crusher plant. Recommended equipment: Impact Crusher. Check out impact crushers for sale at Machinery Partner.

Choose your secondary by application. A cone crusher compresses between a mantle and bowl liner for excellent shape on medium to hard rock. An HSI impactor uses high-speed impact to create a more cubical product. If you need finer shaping or manufactured sand, add a tertiary stage with VSI crushers.

Need help choosing the best crusher for your needs? Check out this blog!

Step 4 – Screening

During the screening phase of the stone crushing process, material is separated by vibrating screeners according to size and moved into separate stockpiles. Screeners allow us to filter and sort the crushed stone before it is either sent back for further crushing or stockpiled into their final grades. Screeners come in a range of sizes and can separate your output into three different sizes. Recommended equipment: Mobile Scalper Screen

Dial in screen media for your application. Wire cloth, rubber, or punch plate will change throughput and cut size. A closed-circuit layout sends oversize back to the crusher to maintain spec gradation and reduce waste.

Step 5 – Conveying

Conveyors link your crushing setup together and move your material from feeder to crushers, screeners or bins. Mobile radial conveyors are great for this task since you won’t need to shut down the whole plant to move your crushers. Mobile conveyors can quickly be moved to set up another stockpile. Recommended equipment: Conveyors

Well-sized conveyors raise stockpile heights, cut loader cycles, and keep each crusher machine fed. Integrate sensors into the control system to balance feeder speed with crusher load.

Before you start crushing stone

Think about your crushing needs. Are you looking for a plant that can handle large amounts of material or a crushing setup that will deliver different kinds of crushed product?

Define your output sizes, target tph, and material hardness first. That will drive whether you select a mobile jaw for on-site work, a static cone-led line for high-capacity production, or a hybrid mobile crushing plant.

Here are a few of the most important things to think about before making a selection.

- Cost – How large is your total stone-crushing budget? Spend money on good equipment as it will save you in the long run with maintenance costs. Account for spare parts, wear parts, liner changes, and fuel or power. Higher-quality crushing equipment often lowers lifetime operating costs.

- Mobile or fixed machines – Mobile machines cost more than fixed equipment. But, being able to move them around the stone crusher plant is a huge advantage. Mobile crusher setups can follow the job and reduce trucking, while fixed installations shine for very high-capacity, continuous production.

- DOT approval – Does your material require government Department of Transport approval? If so, your crushing setup will need to be designed with either an impact crusher or a screener. DOT work often prefers cubical product and tight gradation. Plan for an HSI or VSI plus precise screening to hit spec.

- Materials – Are you crushing hard or soft rock? Will your materials be wet or dry? What final output size will you require? This really important to think about when designing your plant. For more information take a look at this article on how to crush stone. Hard rock favors compression crushers like a cone. Softer, friable material may suit impactors. Moisture affects screen efficiency, so consider dust control and water management.

What other machines can I add to my stone crushing plant?

Aside from the equipment we’ve already mentioned, you may need other machines to improve your stone crusher plant.

- Gyratory crushers – can be used in place of jaw crushers for primary crushing and are ideal for harder materials.

- Cone crushers – are a great alternative to impact crushers and are better for producing less flat and flaky products.

- Other types of conveyors– can be added to the plant giving you more choices and flexibility for moving your materials and linking stations.

- Other types of screeners – may be required for different product needs. Check out this helpful article on screening media.

Additional options include roll crusher installations for top-size control, VSI crushers for shaping, or, in mineral processing contexts, downstream grinding such as a ball mill. Consider auto-lube systems and hydraulic relief to protect equipment and reduce unplanned downtime.

Do I need a permit to run a stone crushing plant?

Understand Regulatory and Environmental Requirements

Setting up a stone crusher plant isn't just about getting the right machines. You’ll also need to make sure your operation follows all local, state, and federal regulations. Failing to plan for this early on can delay your setup and cost you thousands in penalties or forced shutdowns.

Expect rules on air quality, dust suppression, noise, stormwater, and operating hours, particularly near residential zones. Water sprays and baghouse dust collectors can help compliance.

Get the Right Permits and Licenses

Before you break ground, you’ll need to secure permits based on your region’s zoning laws, environmental guidelines, and safety requirements. This often includes:

- Business operation license

- Air quality permits

- Noise and dust control approval

- Zoning or land use clearances

In some areas, you may also need a permit for material handling or mining activities, depending on the source of your stone. Build permitting timelines into equipment delivery so commissioning aligns with approvals.

Prepare an Environmental Impact Assessment (EIA)

If you’re processing large volumes of material or operating in a sensitive area, you may be required to submit an Environmental Impact Assessment (EIA). This document outlines how your plant will manage:

- Dust emissions

- Noise pollution

- Wastewater runoff

- Fuel and oil handling

Even if an EIA isn’t required by law, taking proactive steps to reduce environmental impact is good practice, especially if your site is near residential areas or protected land. Good neighbor plans that address traffic routing for dump trucks, dust control, and hours of operation reduce complaints and risk.

Follow Local and Federal Regulations

Compliance looks different in every state and country, but most areas have rules about:

- Maximum noise levels during operation

- Dust control measures like water suppression or baghouses

- Operating hours, especially in residential zones

- Safe distances from schools, homes, or wetlands

It’s your responsibility to research and meet these requirements before equipment goes live. If you're unsure where to start, many contractors choose to work with local consultants or environmental engineers during the planning phase.

Document SOPs so new operators follow the same control system settings and safety standards every shift.

Finding the right partner to get your stone crusher plant setup

At Machinery Partner, we understand that setting up a stone crusher plant can be challenging, so we’re here to help you with everything you need. We offer a full range of equipment, with high-quality machinery for each stage of your plant.

Our dedicated experts are masters at designing custom plants suited to handle your unique stone-crushing needs. Our Aggflow technology simulates plant flows to ensure you’re getting the most out of your crushing plant, and our financing options make purchasing your plant machinery easy and affordable.

We also help plan spare parts and wear parts so you maintain uptime and predictable operating costs.

FAQs: Stone Crusher Plant Setup

What is the typical lifespan of a stone crusher plant?

With proper maintenance, most stone crusher plants can operate for 15 to 20 years or more. Key components like jaw plates, bearings, belts, and screens will wear out over time, but the core structure of the plant is built to last. Replacing high-wear parts regularly keeps your operation running efficiently and extends the overall life of the system.

How often should maintenance be performed?

Most crushing equipment requires daily checks and weekly maintenance, especially around high-wear zones like the crusher chamber, belts, and screens. Expect to:

- Grease bearings daily

- Inspect wear plates weekly

- Check conveyor tension weekly

- Schedule a full inspection every 250 to 500 operating hours

Preventative maintenance helps you avoid breakdowns, reduces downtime, and keeps production on schedule. Many operators use digital logbooks or apps to stay consistent with service intervals. Add remote monitoring where available to track load, temperature, and vibration through the control system.

Can the plant be upgraded or expanded in the future?

Yes. Many stone crusher plants are built in modular stages, so you can add equipment as demand grows. Common upgrades include:

- Adding a secondary or tertiary crusher to increase output or produce different sizes

- Installing a scalping screen to pre-sort material before crushing

- Adding conveyors or a radial stacker to reduce loader use

- Upgrading the control system for better automation and safety

When you choose the right layout and leave space for future expansion, your plant can grow alongside your business.

How much does it cost to set up a stone crusher plant?

Costs vary based on throughput capacity, material type, and equipment choices. A basic setup with a jaw crusher, screen, and conveyors might start around $100,000 to $250,000, while more advanced systems with secondary crushers and automation can exceed $500,000. Many small contractors start with a single-stage crusher and scale up as volume grows.

What type of material can be crushed?

Stone crusher plants can handle a range of material types, including:

- Granite

- Basalt

- Limestone

- River rock

- Recycled concrete and asphalt

Make sure the crusher you choose is rated for your material’s hardness and abrasiveness. For example, jaw crushers are great for hard rock, while impact crushers are better for softer or friable materials.

Do I need a power source on site?

Yes. Most plants run on either diesel generators, electric hookups, or hybrid systems. If you're working in a remote area, a diesel-powered setup might be easier to deploy. In urban or high-volume settings, electric power may reduce fuel costs and simplify maintenance. Hybrid systems help smooth load spikes during peak crushing and cut fuel burn.